The Systems tab within Simergy contains a number of different workspace types. The sections provide a screenshot (a visual) of the workspace, which highlights the main workspace capability areas, and a portal to descriptions (the detail) of the capability sections. The workspace list is expressed as the ribbon section and then the workspace area name. In this case each listing on the ribbon presents a slightly different workspace, results in eight main workspaces on the Systems tab (including the common Import and Export workspaces)

|

||

|

|

|

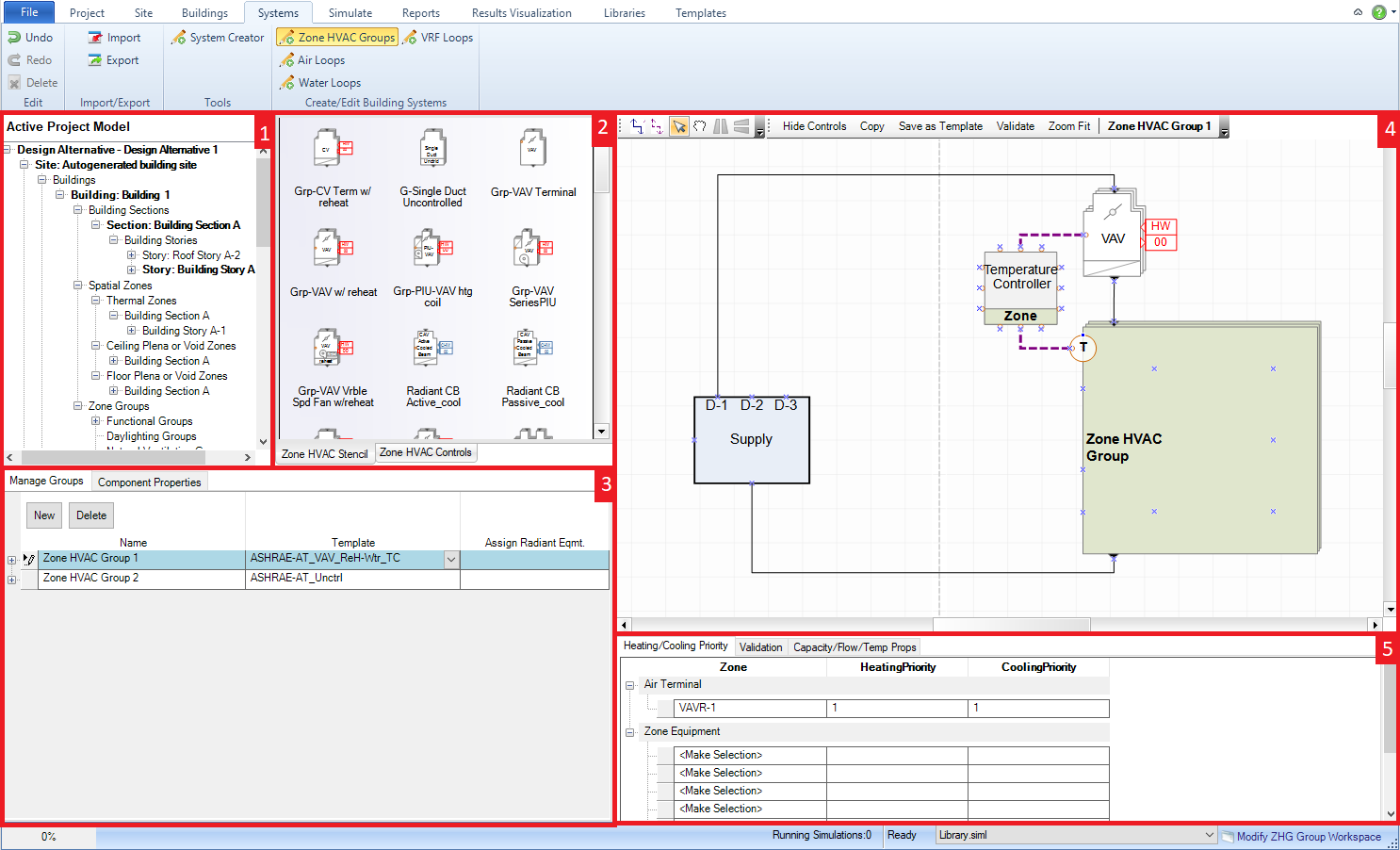

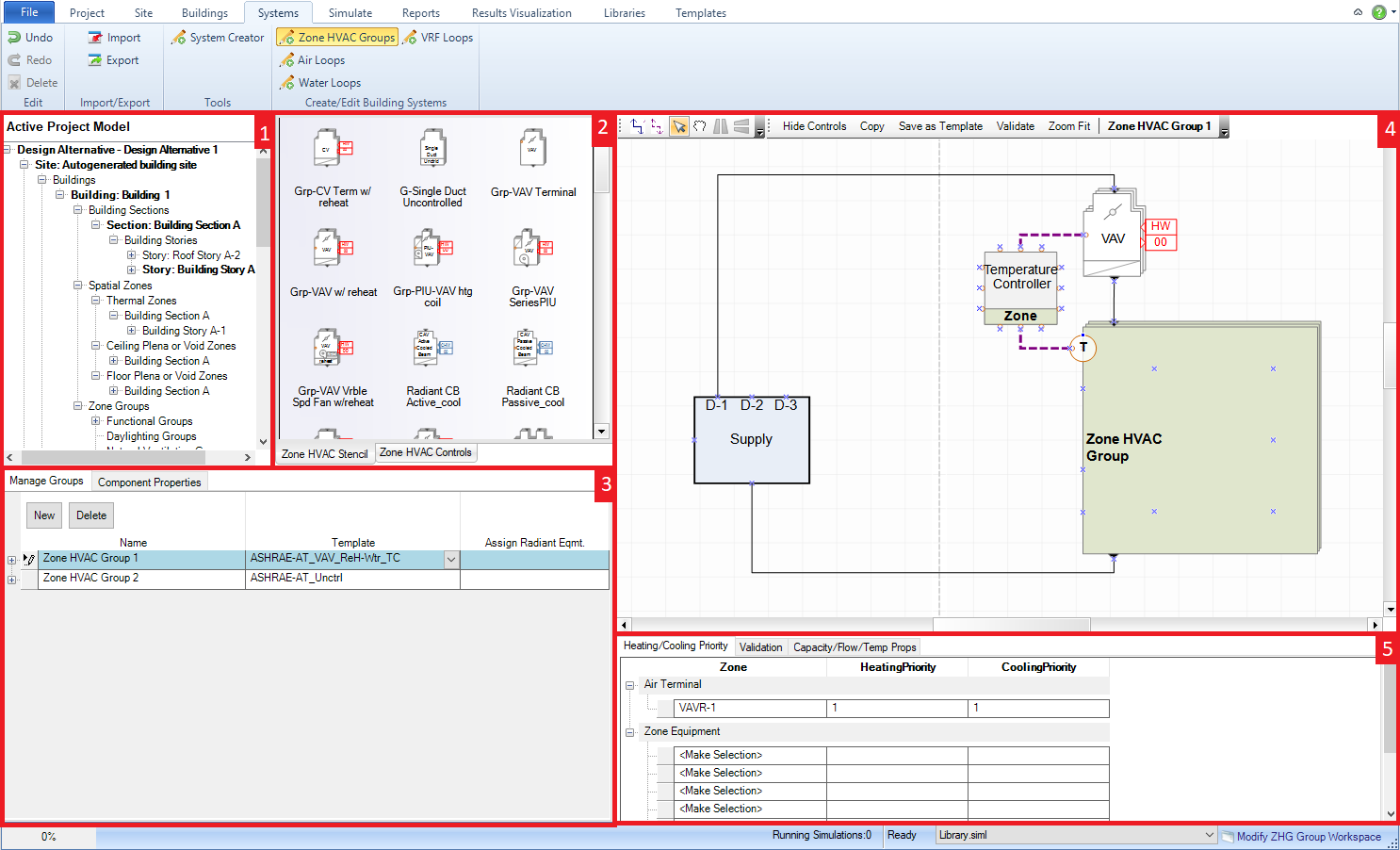

The workspace where users can define Zone HVAC Groups, associate thermal zones with the Zone HVAC Groups and assign Zone HVAC Equipment templates to the Zone HVAC Groups to define the demand side for the air loops.

Main workspace areas:

Project/Component Tree (top left) - allows the user to select single or multiple thermal zones and add them to a Zone HVAC Group by dragging and dropping them on the targeted Zone HVAC Group name.

HVAC diagramming stencils - Zone HVAC Stencil and Zone HVAC Controls & Sensors stencils are both options to the user and they are made active by just selecting on the stencil title. The Zone HVAC stencil is the default and shows icons with titles to describe the available Zone HVAC equipment that can be incorporated into the Zone HVAC Group. Shape components can be selected from the Stencil and then dragged and dropped on the HVAC diagramming canvas to be incorporated into the Zone HVAC Group. Each shape component has anchor points, which assist placing the shape components. Those anchor points will snap to the anchor points (blue x) that are located within the Zone HVAC Group shape and indicate a maximum number of shape components that can be associated with a Zone HVAC Group.

Zone HVAC

Groups (bottom left) - allows the user to define what every

Simergy model must have, at least one Zone HVAC Group. Unlimited

Zone HVAC Groups can be added to the model by selecting New. For

each Zone HVAC Group the user can add single or multiple thermal zones

by dragging and dropping the thermal zones from the Project/Component

Tree. Once a Zone HVAC Group has one thermal zone associated

with it, then the template column becomes active and the user can

select from the available templates in the drop down list or they

can create there own. Selecting a template establishes the demand

side configuration for this Zone HVAC Group within the Air Loop. Tip: The Zone HVAC Group that is selected will be the

Zone HVAC Group template displayed in the Diagram Workspace

Selected

Component Information - when the user selects a component

from the HVAC diagramming canvas, that component's property information

will appear in this field. The type of properties displayed

will vary significantly component to component, however the line items

shown above the table are common fields. For those users that

are familiar with the Input Data File (IDF) structure, the property

list for each component is aligned with that list. For each component

Type, Sub Types and Library Entities will be shown, while shapes that

contain off-page reference tags will potentially have up to four additional

line items for each of the water loop types (HW, CHW, MxW, CW). Tip: Make sure a component has a Library Entity specified,

otherwise the BEM will not simulate.

HVAC diagramming canvas - paints the picture of the components, sensors and controls associated with the Zone HVAC Group. The Zone HVAC Group can be validated and a number of other capabilities are at the users fingertips (think tip of the iceberg).

System Level Controls/ Validation -This field has tabs for setting the heating/cooling priority and a second tab for displaying validation findings. The user can set the heating and cooling priority for air terminals and zone equipment separately. When equipment is added to the Zone HVAC Group the name of the component will automatically be added to the table. To set the priority the user must select the priority number for both heating and cooling from the drop down list. If the user selects Validate on the HVAC diagramming canvas the validation results (name, system issue to be fixed, and error type) will be displayed on the Validation tab.

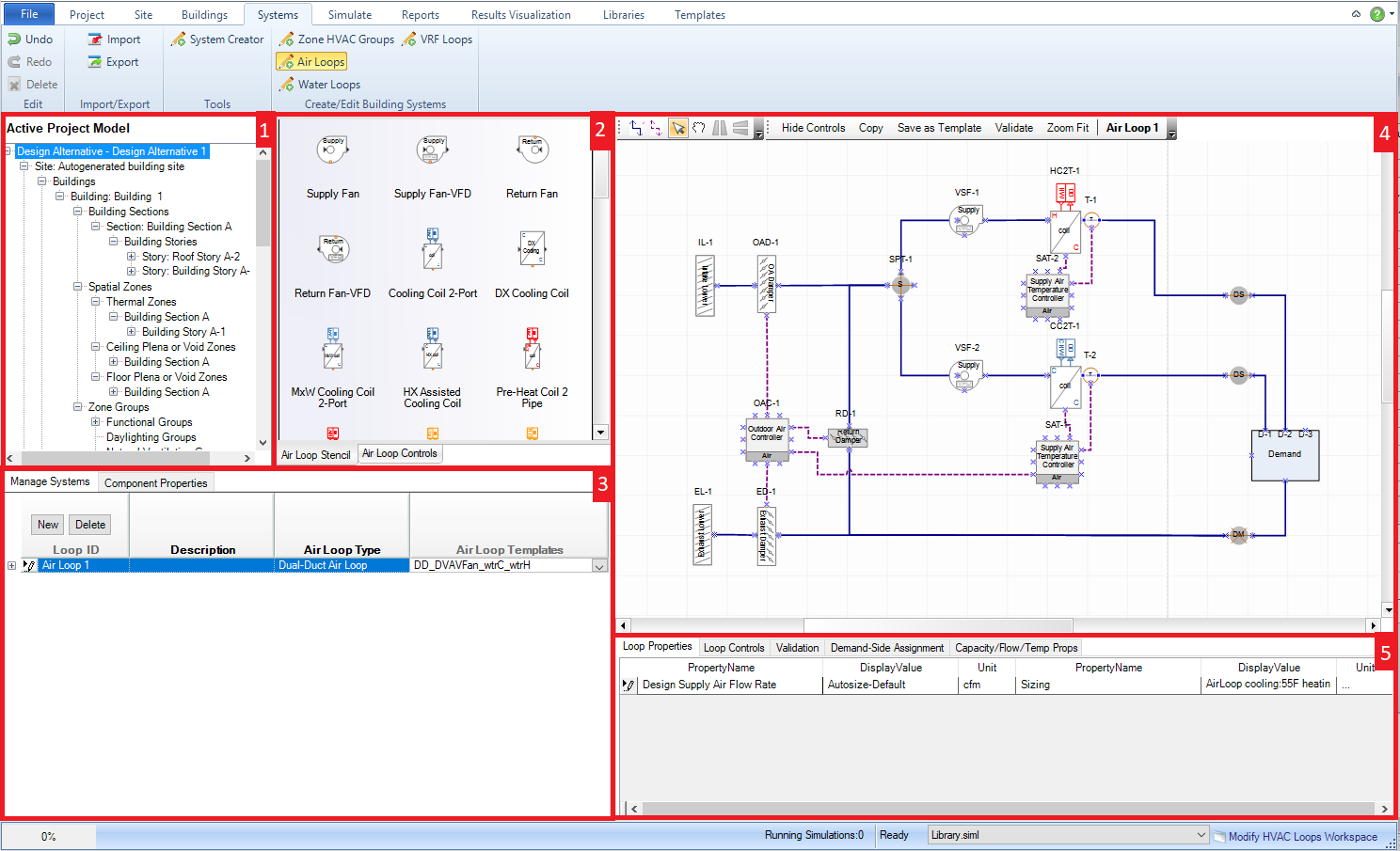

The workspace allows the user to set up a single or multiple air loops by selecting an Air Loop Template (defining supply side) and assigning Zone HVAC Groups (defining demand side) to them. Once these templates have been assigned then the user can visualize the Air Loop Diagram and they can assign system parameters as well.

Main workspace areas include:

Project/Component Tree (top left) - Zone HVAC Groups can be highlighted and then dragged and dropped onto the Air Loop ID name to assign those Zone HVAC Groups to the Air Loop. Once that has been done the Zone HVAC Group diagrams will be shown on the demand side of the Air Loop.

HVAC diagramming stencils - Air Loop Stencil and Air Loop Controls & Sensors stencils are both options to the user and they are made active by just selecting on the stencil title. The Air Loop stencil is the default and shows icons with titles to describe the availableAir Loop equipment that can be incorporated into the Air Loop. Shape components can be selected from the Stencil and then dragged and dropped on the Air Loop diagramming canvas to be incorporated into the Air Loop. Each shape component has anchor points, which assist placing the shape components. Those anchor points will snap to the anchor points (blue x) that are located within the Air Loop shape and indicate a maximum number of shape components that can be associated with an Air Loop.

Air System

Groups (bottom left) - allows the user to build or delete

single or multiple air loops. The supply side and demand side

need to be established to set up the Air Loop. The Supply side

can be established by selecting an Air Loop Template from the drop

down list in that column. The Air Loop Template could just serve

as the starting point for the loop design that can then be edited

in the Diagram workspace. The demand side is defined by applying

the Zone HVAC groups to the Air Loop, which can be done by dragging

and dropping them from the Project Component Tree. Once a Zone

HVAC Group is applied the default Demand Side Shape is replaced with

the Zone HVAC Group diagram.

Selected

Component Information (Properties) - when the user selects

a component from the HVAC diagramming canvas property information

will appear in this field. The type of properties displayed

will vary significantly component to component, however the line items

shown above the table are common fields. For those users that

are familiar with the Input Data File (IDF) structure, the property

list for each component is aligned with that list. For each component

Type, Sub Types and Library Entities will be shown, while shapes that

contain off-page reference tags will potentially have up to four additional

line items for each of the water loop types (HW, CHW, MxW, CW). Tip: Make sure a component has a Library Entity specified,

otherwise the BEM will not simulate.

HVAC diagramming canvas - paints the picture of the Air Loop Design for the supply and demand side based on the templates that have been applied. The user can view other Air Loop Designs by selecting a different Air Loop from the Air Loop Groups. In addition the user can choose to hide the controls to display a simpler loop design picture or show the controls to get the complete picture. The only thing the user can't do is select components and start editing the loop design. To do that they need to go to the Diagram Workspace. Tip: the Zoom to Fit button can be very useful when the user is investigating different aspects of the Air Loop design.

Air System Parameters (bottom right) - allows the user to set parameters, such as sizing criteria, at the overall Air Loop level.

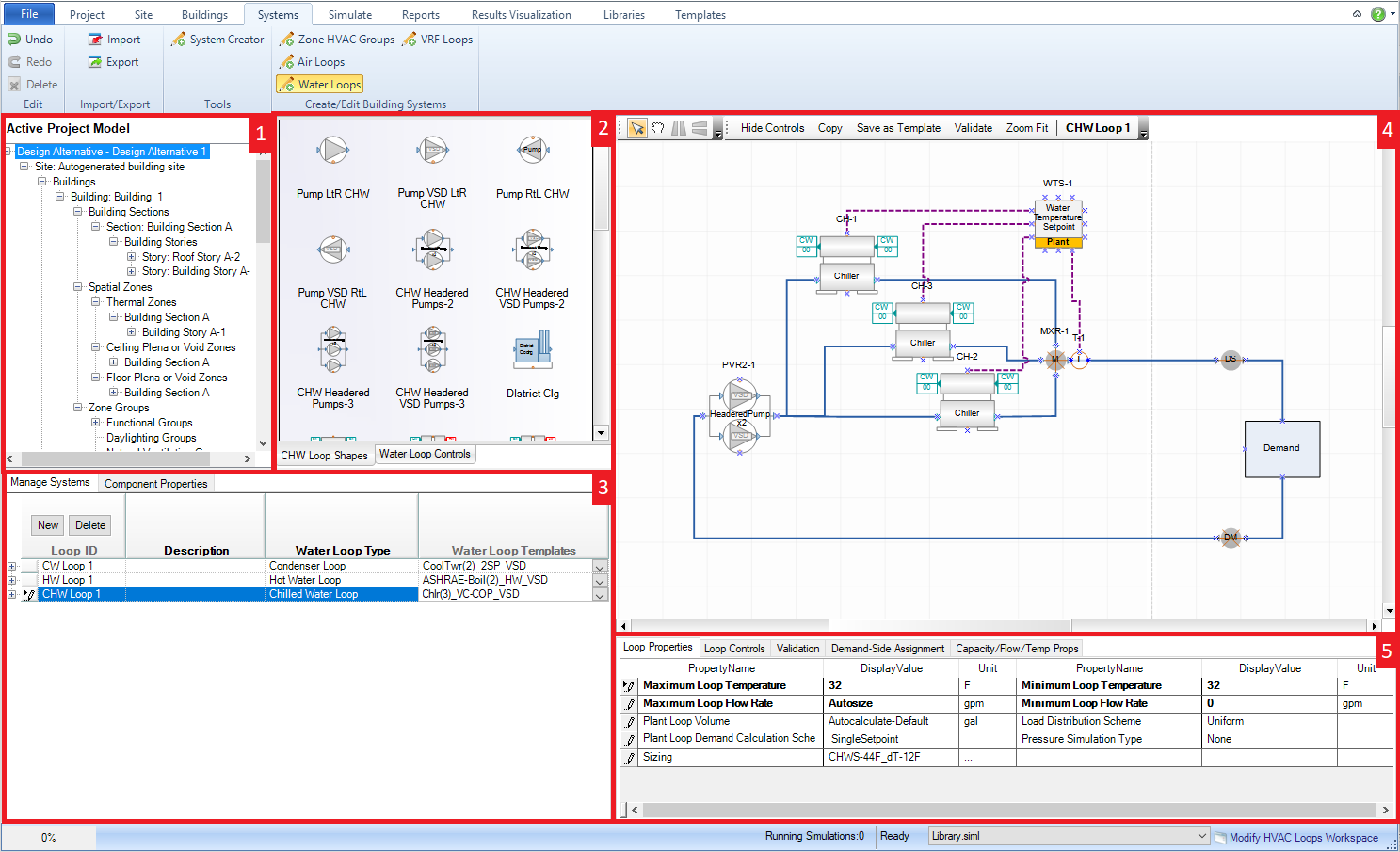

Main workspace areas include:

Project/Component Tree (top left) - Zone HVAC Groups can be highlighted and then dragged and dropped onto the Air Loop ID name to assign those Zone HVAC Groups to the Air Loop. Once that has been done the Zone HVAC Group diagrams will be shown on the demand side of the Air Loop.

Water Loop Diagramming stencils - Water Loop Stencil and Water Loop Controls & Sensors stencils are both options to the user and they are made active by just selecting on the stencil title. The Water Loop stencil is the default and shows icons with titles to describe the available Water Loop equipment that can be incorporated into the Water Loop. Shape components can be selected from the Stencil and then dragged and dropped on the Water Loop diagramming canvas to be incorporated into the Water Loop. Each shape component has anchor points, which assist placing the shape components. Those anchor points will snap to the anchor points (blue x) that are located within the Water Loop shape and indicate a maximum number of shape components that can be associated with an Water Loop.

Water

System Loops (bottom left) - allows the user to create

or delete single or multiple water loops. The user can create

Hot Water, Chilled Water, Condenser Water or Mixed Water Loops by

selecting New. The user can then select a Water Loop Template

from the available selections or go to the Templates tab to create

their own. Once a template has been applied the

supply side of the water loop will be displayed on the HVAC diagramming

canvas with the demand side demand box shape placeholder. The

demand side will appear once the water loops have been assigned to

the components with off-page references that are included in the other

loops. The user can view different water loops by selecting

on the different water loops.

Selected

Component Information (Properties) - when the user selects

a component from the HVAC diagramming canvas property information

will appear in this field. The type of properties displayed

will vary significantly component to component, however the line items

shown above the table are common fields. For those users that

are familiar with the Input Data File (IDF) structure, the property

list for each component is aligned with that list. For each component

Type, Sub Types and Library Entities will be shown, while shapes that

contain off-page reference tags will potentially have up to four additional

line items for each of the water loop types (HW, CHW, MxW, CW). Tip: Make sure a component has a Library Entity specified,

otherwise the BEM will not simulate.

HVAC diagramming canvas - paints the picture of the Water Loop Design for the supply and demand side based on the templates that have been applied. The user can choose to hide the controls to display a simpler loop design picture or show the controls to get the complete picture. The only thing the user can't do is select components and start editing the loop design. To do that they need to go to the Diagram Workspace.

Water System Parameters (bottom right) - allows the user to set parameters, such as sizing criteria, at the overall Water Loop level.

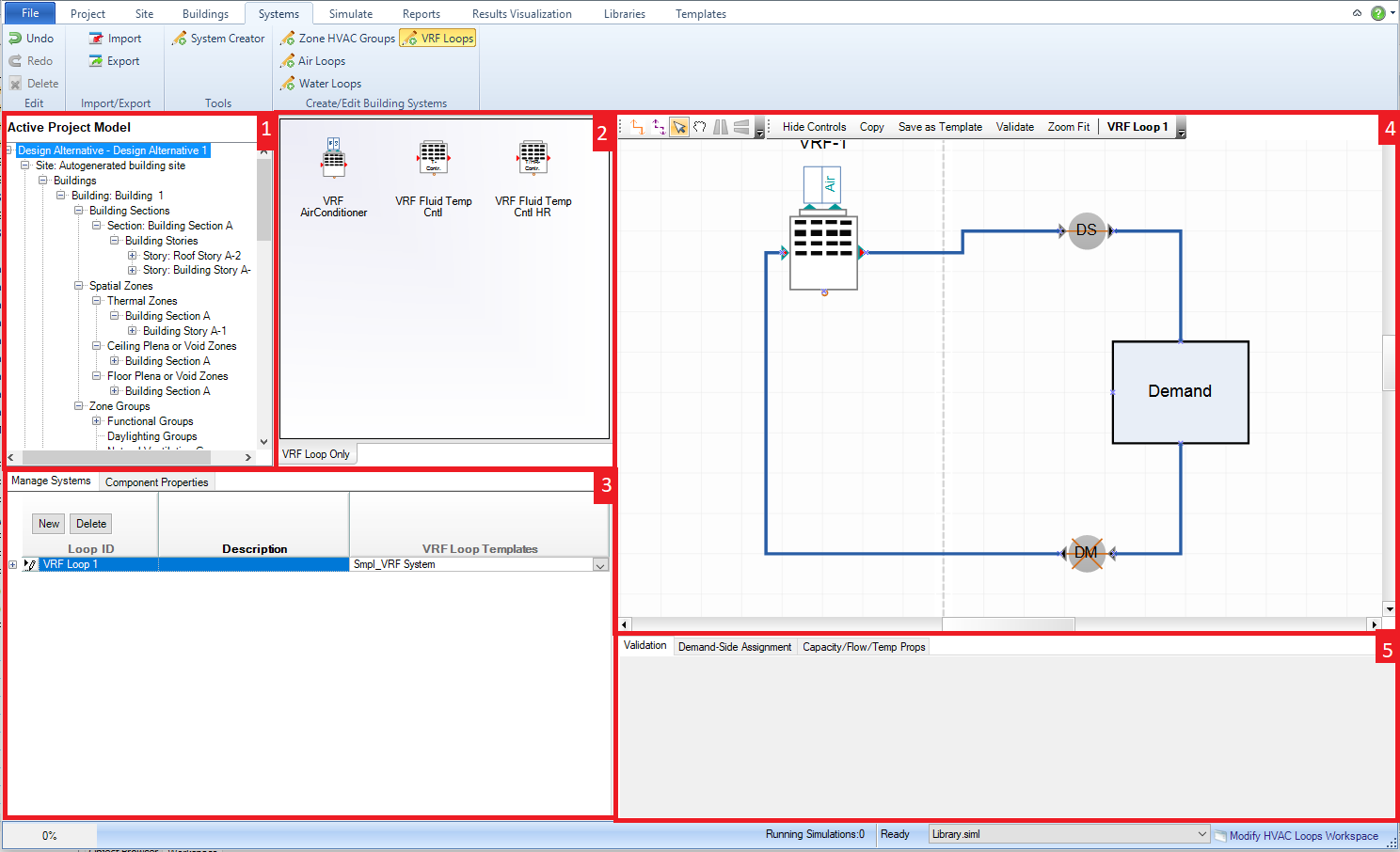

Main workspace areas include:

Project/Component Tree (top left) - Zone HVAC Groups can be highlighted and then dragged and dropped onto the Air Loop ID name to assign those Zone HVAC Groups to the Air Loop. Once that has been done the Zone HVAC Group diagrams will be shown on the demand side of the Air Loop.

VRF Loop Diagramming stencils - VRF Loop Stencil and VRF Loop Controls & Sensors stencils are both options to the user and they are made active by just selecting on the stencil title. The VRF Loop stencil is the default and shows icons with titles to describe the available VRF Loop equipment that can be incorporated into the WaVRF ter Loop. Shape components can be selected from the Stencil and then dragged and dropped on the VRF Loop diagramming canvas to be incorporated into the VRF Loop. Each shape component has anchor points, which assist placing the shape components. Those anchor points will snap to the anchor points (blue x) that are located within the VRF Loop shape and indicate a maximum number of shape components that can be associated with an VRF Loop.

VRF

System Loops (bottom left) - allows the user to create

or delete single or multiple water loops. The user can create

Hot Water, Chilled Water, Condenser Water or Mixed Water Loops by

selecting New. The user can then select a Water Loop Template

from the available selections or go to the Templates tab to create

their own. Once a template has been applied the

supply side of the water loop will be displayed on the HVAC diagramming

canvas with the demand side demand box shape placeholder. The

demand side will appear once the water loops have been assigned to

the components with off-page references that are included in the other

loops. The user can view different water loops by selecting

on the different water loops.

Selected

Component Information (Properties) - when the user selects

a component from the HVAC diagramming canvas property information

will appear in this field. The type of properties displayed

will vary significantly component to component, however the line items

shown above the table are common fields. For those users that

are familiar with the Input Data File (IDF) structure, the property

list for each component is aligned with that list. For each component

Type, Sub Types and Library Entities will be shown, while shapes that

contain off-page reference tags will potentially have up to four additional

line items for each of the water loop types (HW, CHW, MxW, CW). Tip: Make sure a component has a Library Entity specified,

otherwise the BEM will not simulate.

HVAC diagramming canvas - paints the picture of the Water Loop Design for the supply and demand side based on the templates that have been applied. The user can choose to hide the controls to display a simpler loop design picture or show the controls to get the complete picture. The only thing the user can't do is select components and start editing the loop design. To do that they need to go to the Diagram Workspace.

VRF System Parameters (bottom right) - allows the user to set parameters, such as sizing criteria, at the overall Water Loop level.

Main Workspace areas include:

Project/Component Tree (top left) - to change the Air Loop Diagram that is being worked on in the Diagram workspace, the user can select the desired Air Loop from the tree, right click, and select Diagram Air Loop.

Interactive 3d Model View (middle top) - provides the user a 3d interactive view of the current model to preview site objects that are being and/or have been created

Template Selection Palette- Here the user can select templates for each of the various types of system loops and groups. The selection of system and group templates can be saved as a named "super template" to make applying that specific system and group setup to another model quick and painless. There are also controls to generate the current selection of systems and groups in the current model or to delete all systems and groups in the current model to start from scratch.

System Creator Preview Diagram - this palette displays an interactive diagram showing the systems that will be generated based on the current selections. The user can rename, resize and drag the system markers to visualize the whole network of systems and groups before generating them within the model.

______________________________________________________________________________________

© Copyright 2013 Simergy, Sustainable IQ, Inc.