Input Output Reference

The Encyclopedic Reference to EnergyPlus Input and Output

Date: September 28, 2012

What’s different about EnergyPlus Input and Output?

Input – Output Descriptions (Document)

Group -- Simulation Parameters

SurfaceConvectionAlgorithm:Inside

SurfaceConvectionAlgorithm:Outside

HeatBalanceSettings:ConductionFiniteDifference

ZoneCapacitanceMultiplier:ResearchSpecial

Group -- Location – Climate – Weather File Access

SizingPeriod:WeatherFileConditionType

RunPeriodControl:DaylightSavingTime

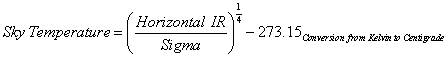

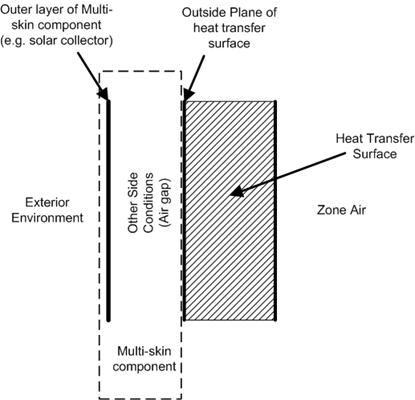

WeatherProperty:SkyTemperature

Site:GroundTemperature:BuildingSurface

Site:GroundTemperature:Shallow

Site:GroundTemperature:FCfactorMethod

Site:GroundReflectance:SnowModifier

Outputs for local temperature/wind speed calculations

Group – Surface Construction Elements

Specifying the Building Envelope

Material and Material Properties

MaterialProperty:MoisturePenetrationDepth:Settings

Moisture Penetration Depth (EMPD) Outputs

MaterialProperty:VariableThermalConductivity

Conduction Finite Difference (CondFD) Outputs

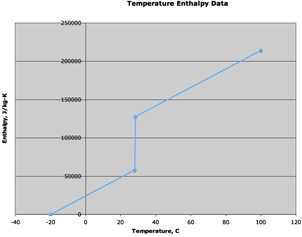

MaterialProperty:HeatAndMoistureTransfer:Settings

MaterialProperty:HeatAndMoistureTransfer:SorptionIsotherm

MaterialProperty:HeatAndMoistureTransfer:Suction

MaterialProperty:HeatAndMoistureTransfer:Redistribution

MaterialProperty:HeatAndMoistureTransfer:Diffusion

MaterialProperty:HeatAndMoistureTransfer:ThermalConductivity

Heat and Moisture (HAMT) Outputs

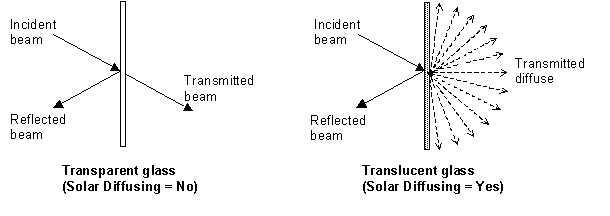

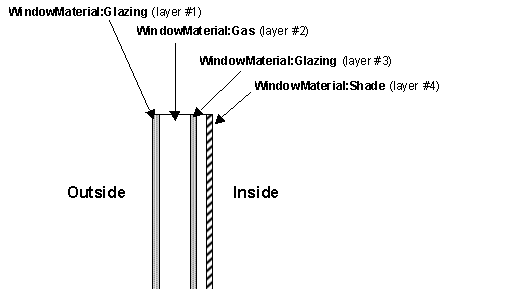

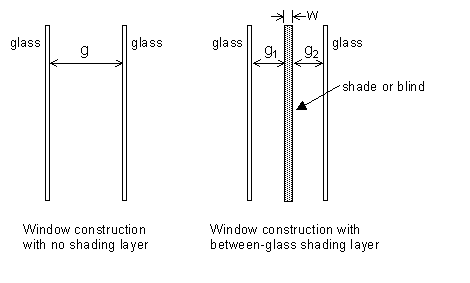

Materials for Glass Windows and Doors

WindowMaterial:Glazing:RefractionExtinctionMethod

Glass Optical Properties Conversion

WindowMaterial:GlazingGroup:Thermochromic

WindowMaterial:GlazingGroup:Thermochromic Outputs

WindowMaterial:SimpleGlazingSystem

MaterialProperty:GlazingSpectralData

Site:GroundTemperature:FCfactorMethod

Construction:CfactorUndergroundWall

Construction:FfactorGroundFloor

Construction:UseHBAlgorithmCondFDDetailed

Group – Thermal Zone Description/Geometry

Surface Output Variables/Reports

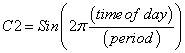

Surface Output Variables (all heat transfer surfaces)

Surface Output Variables (exterior heat transfer surfaces)

Opaque Surface Output Variables

Shading:Site, Shading:Building

Shading:Site:Detailed, Shading:Building:Detailed

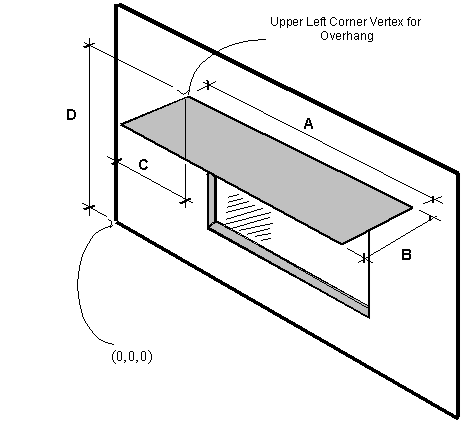

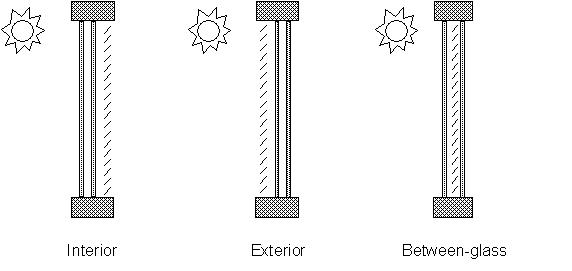

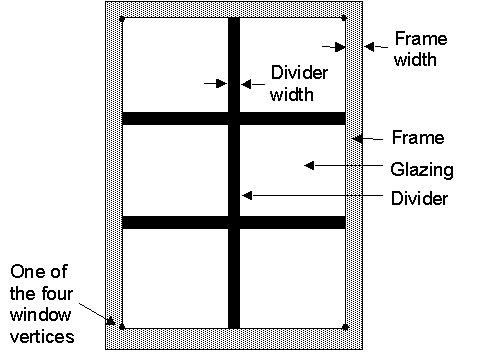

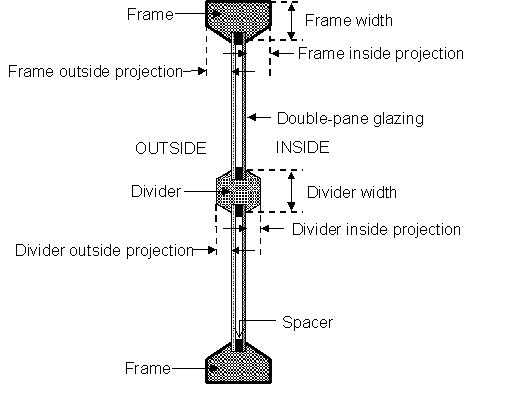

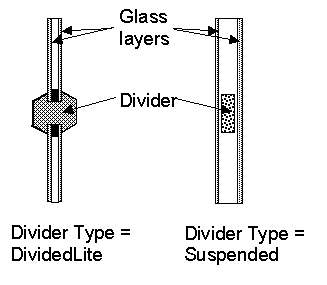

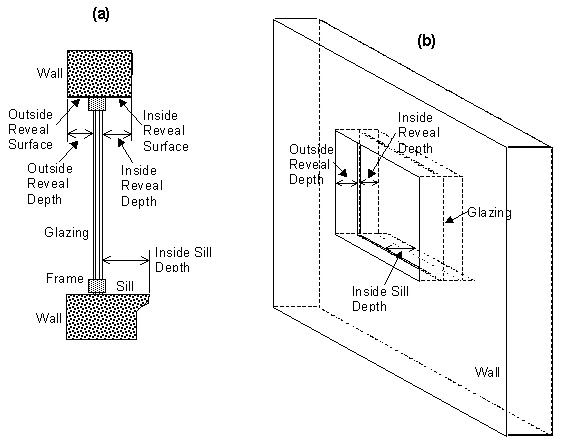

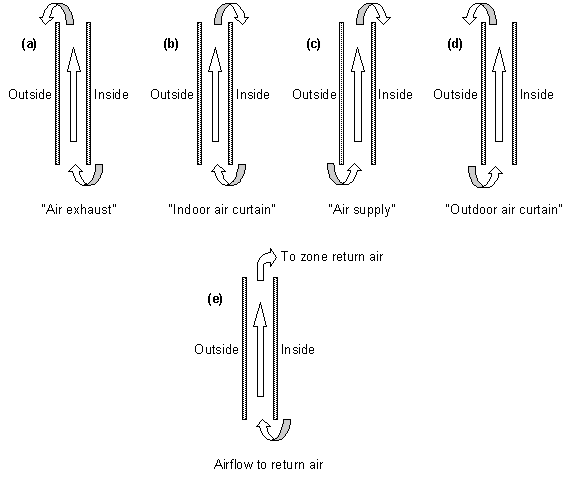

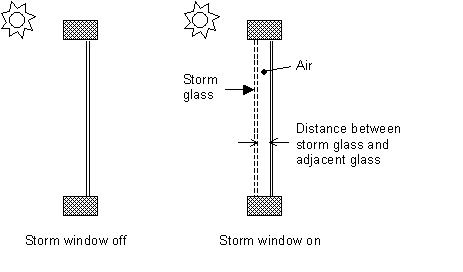

WindowProperty:FrameAndDivider

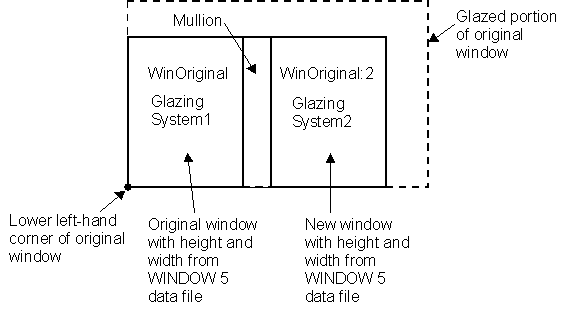

Importing Windows from WINDOW 5

Group – Advanced Surface Concepts

SurfaceControl:MoveableInsulation

SurfaceProperty:OtherSideCoefficients

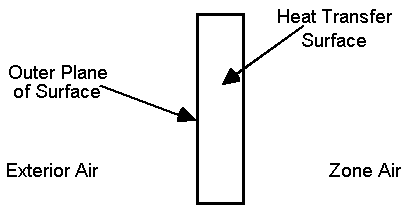

SurfaceProperty:OtherSideConditionsModel

SurfaceConvectionAlgorithm:Inside:AdaptiveModelSelections

SurfaceConvectionAlgorithm:Outside:AdaptiveModelSelections

SurfaceConvectionAlgorithm:Inside:UserCurve

SurfaceConvectionAlgorithm:Outside:UserCurve

SurfaceProperty:ConvectionCoefficients

SurfaceProperty:ConvectionCoefficients:MultipleSurface

Convection Coefficient Application Hierarchy

Convection Coefficients Outputs

SurfaceProperties:VaporCoefficients

SurfaceProperty:ExteriorNaturalVentedCavity

SurfaceProperty:ExteriorNaturalVentedCavity Outputs

ZoneProperty:UserViewFactors:bySurfaceName

Group – Detailed Ground Heat Transfer

RoomAir:TemperaturePattern:UserDefined

RoomAir:TemperaturePattern:ConstantGradient

RoomAir:TemperaturePattern:TwoGradient

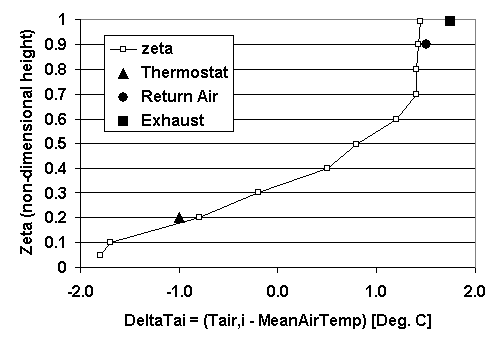

RoomAir:TemperaturePattern:NondimensionalHeight

RoomAir:TemperaturePattern:SurfaceMapping

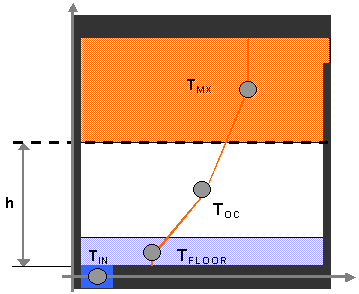

RoomAirSettings:OneNodeDisplacementVentilation

RoomAirSettings:ThreeNodeDisplacementVentilation

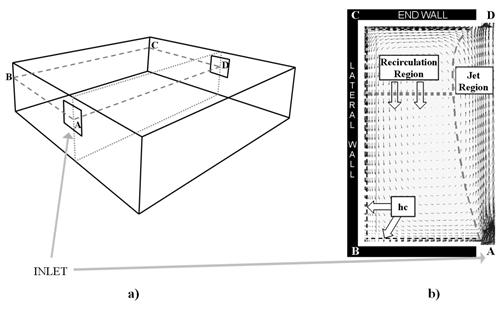

RoomAirSettings:CrossVentilation

RoomAirSettings:UnderFloorAirDistributionInterior

RoomAirSettings:UnderFloorAirDistributionExterior

RoomAir:TemperaturePattern:TwoGradient Outputs

Mundt Model / OneNodeDisplacementVentilation Outputs

ThreeNodeDisplacementVentilation Outputs

CrossVentilation Model Outputs

UnderFloorAirDistributionInterior/Exterior Model Outputs

Group – Internal Gains (People, Lights, Other internal zone equipment)

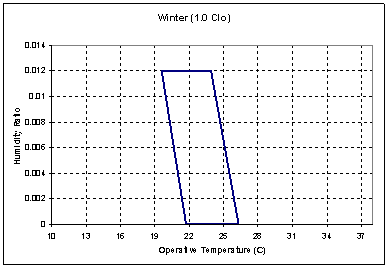

Simplified ASHRAE 55-2004 Graph Related Outputs

Electric, Gas, Other, HotWater, Steam Equipment Outputs

ZoneContaminantSourceAndSink:CarbonDioxide

ZoneContaminantSourceAndSink:CarbonDioxide Outputs

ZoneBaseboard:OutdoorTemperatureControlled

ZoneBaseboard:OutdoorTemperatureControlled Output

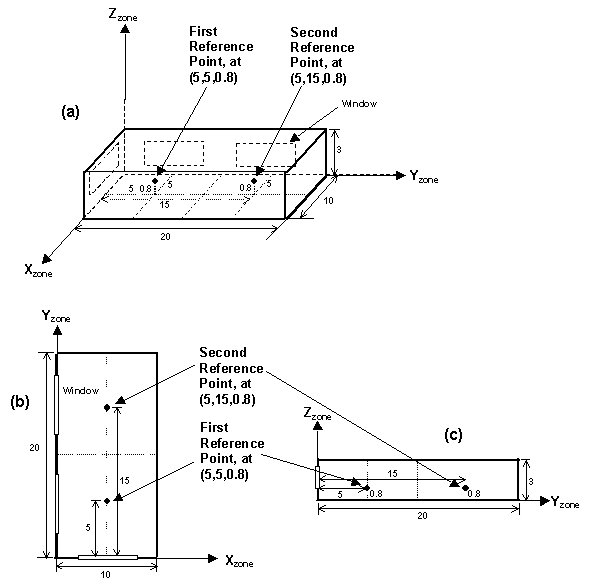

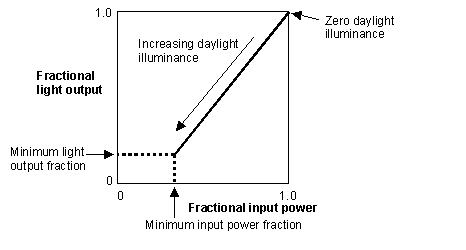

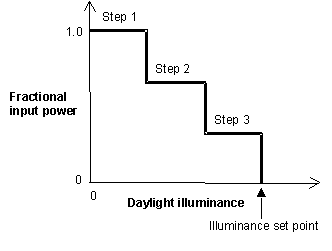

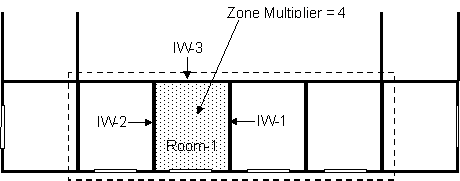

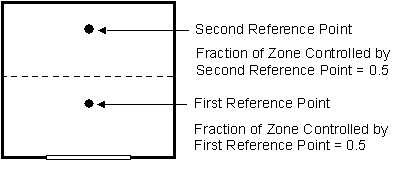

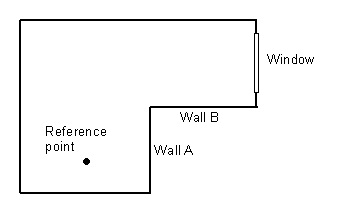

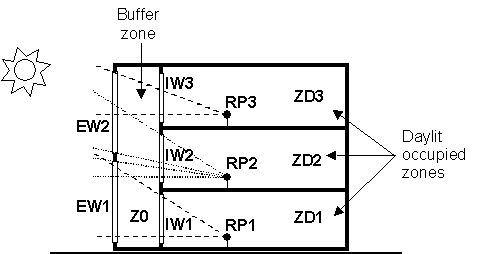

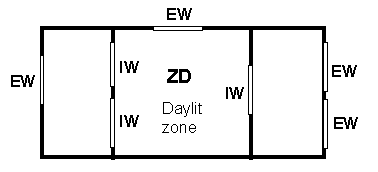

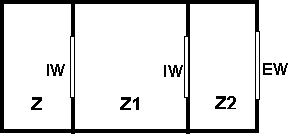

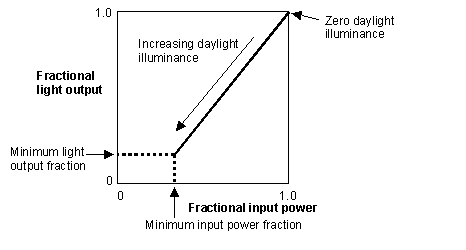

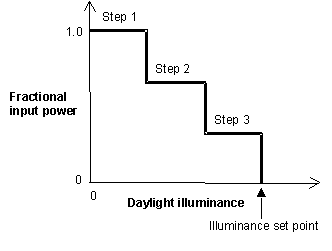

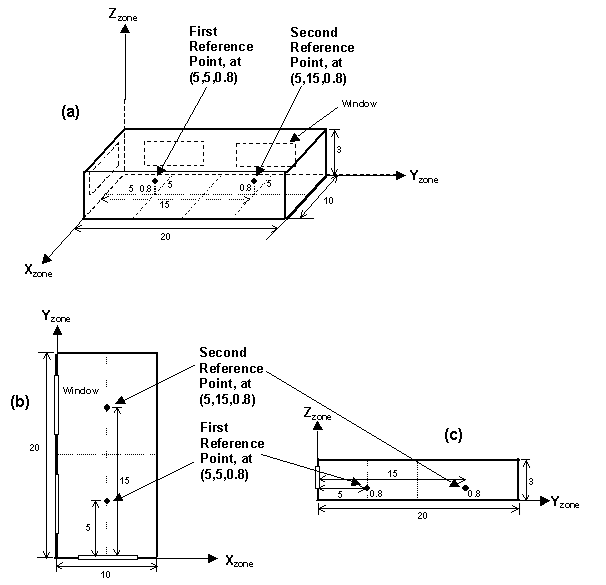

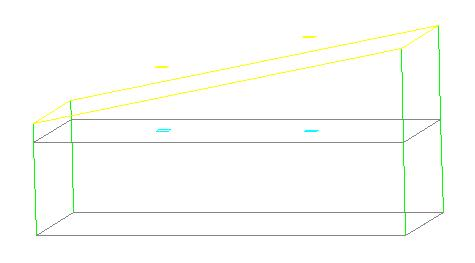

Guidelines for Daylighting Modeling (Detailed Method)

Daylighting:DELight:ReferencePoint

Daylighting:DELight:ComplexFenestration

OutputControl:IlluminanceMap:Style

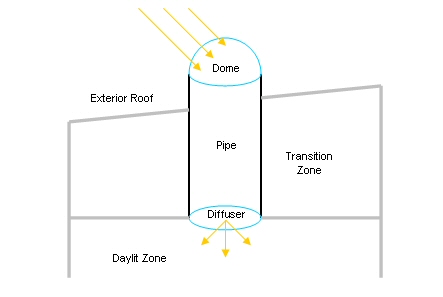

Tubular Daylighting Device Output

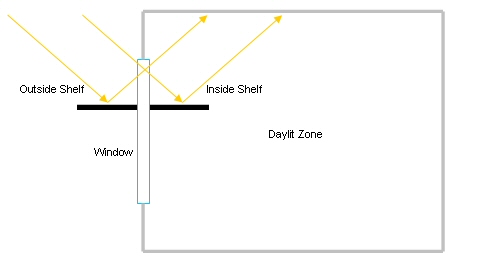

Shelf Daylighting Device Output

Group – Exterior Energy Use Equipment

Exterior Fuel Equipment, Exterior Water Equipment Outputs

ZoneInfiltration:DesignFlowRate

ZoneInfiltration:EffectiveLeakageArea

ZoneInfiltration:FlowCoefficient

ZoneVentilation:DesignFlowRate

ZoneVentilation:WindandStackOpenArea

ZoneAirBalance:OutdoorAir Outputs

Refrigeration Door Mixing Outputs

ZoneThermalChimney (Thermal Chimney)

Input for Design Calculations and Component Autosizing

DesignSpecification:OutdoorAir

HVAC: Primary and Secondary Systems

Group – Node-Branch Management

PipingSystem:Underground Class Objects

PipingSystem:Underground:Domain

PipingSystem:Underground:PipeCircuit

PipingSystem:Underground:PipeSegment

PipingSystem:Underground Outputs

Group – Plant-Condenser Control

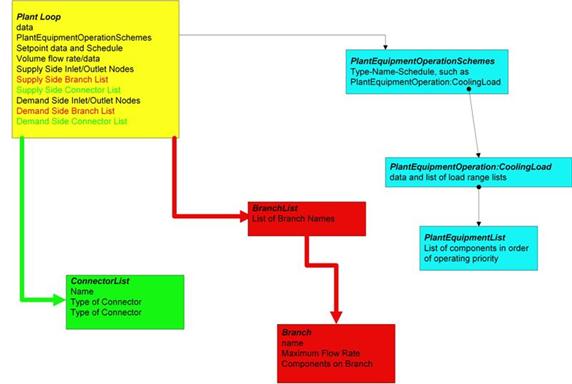

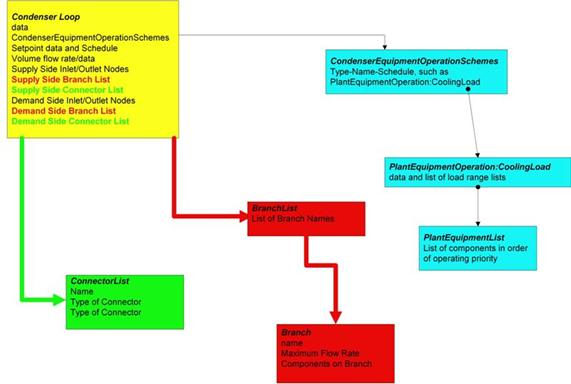

Operation Schemes (Plant and Condenser)

PlantEquipmentOperationSchemes

CondenserEquipmentOperationSchemes

PlantEquipmentOperation:Uncontrolled

PlantEquipmentOperation:CoolingLoad

PlantEquipmentOperation:HeatingLoad

PlantEquipmentOperation:OutdoorDryBulb

PlantEquipmentOperation:OutdoorWetBulb

PlantEquipmentOperation:OutdoorRelativeHumidity

PlantEquipmentOperation:OutdoorDewpoint

PlantEquipmentOperation:OutdoorDryBulbDifference

PlantEquipmentOperation:OutdoorWetBulbDifference

PlantEquipmentOperation:OutdoorDewpointDifference

PlantEquipmentOperation:ComponentSetpoint

Indirect Absorption Chiller Outputs

Chiller:Electric:ReformulatedEIR

Electric Reformulated EIR Chiller Outputs

Combustion Turbine Chiller Outputs

ChillerHeater:Absorption:DirectFired

Direct Fired Absorption Chiller Outputs

ChillerHeater:Absorption:DoubleEffect

Exhaust Fired Absorption Chiller Outputs

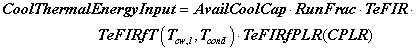

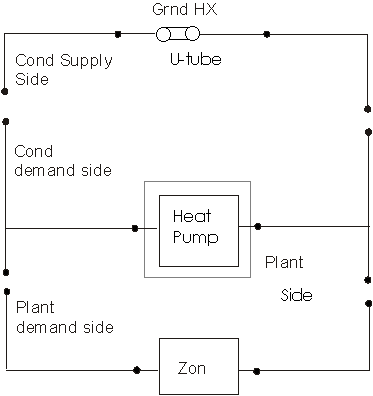

HeatPump:WaterToWater:EquationFit:Cooling

HeatPump:WaterToWater:EquationFit:Heating

HeatPump:WaterToWater:ParameterEstimation:Cooling

HeatPump:WaterToWater:ParameterEstimation:Heating

Water to Water Heat Pump Parameter Estimation Outputs

Water to Water Heat Pump Equation Fit Outputs

Thermal Storage:Ice:Simple Outputs

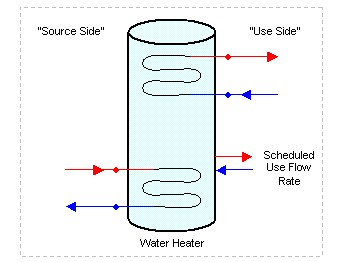

ThermalStorage:ChilledWater:Mixed

ThermalStorage:ChilledWater:Mixed Outputs

ThermalStorage:ChilledWater:Stratified

ThermalStorage:ChilledWater:Stratified Outputs

Water Heater:Stratified Outputs

CoolingTower:SingleSpeed Outputs

Cooling Tower:Two Speed Outputs

Cooling Tower:Variable Speed Outputs

CoolingTowerPerformance:CoolTools

CoolingTowerPerformance:CoolTools Outputs

CoolingTowerPerformance:YorkCalc

CoolingTowerPerformance:YorkCalc Outputs

EvaporativeFluidCooler:SingleSpeed

EvaporativeFluidCooler:SingleSpeed Outputs

EvaporativeFluidCooler:TwoSpeed

EvaporativeFluidCooler:TwoSpeed Outputs

FluidCooler:SingleSpeed Outputs

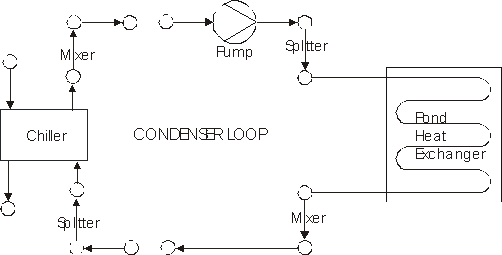

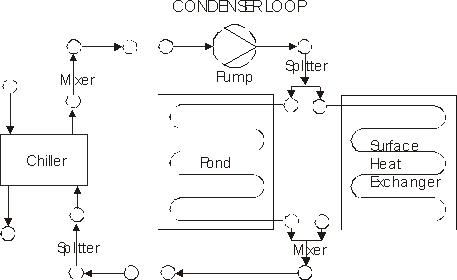

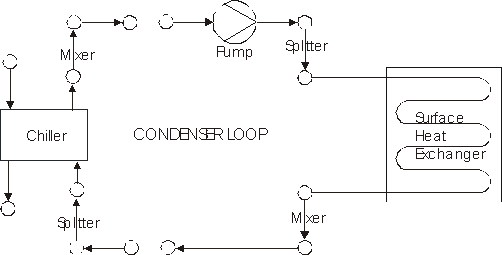

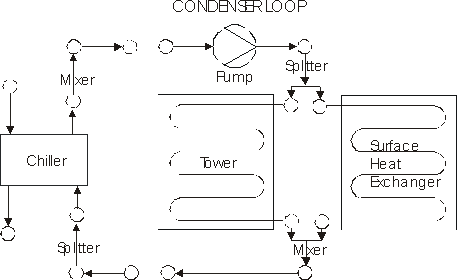

Surface Heat Exchanger Outputs

HeatExchanger:Hydronic Outputs

HeatExchanger:WatersideEconomizer

HeatExchanger:WatersideEconomizer Outputs

Group – Plant-Condenser Flow Control

Connector:Splitter, Connector:Mixer

Outdoor Air Ventilation Report Variables

System Component Loads Outputs

System Component Energy Use Outputs

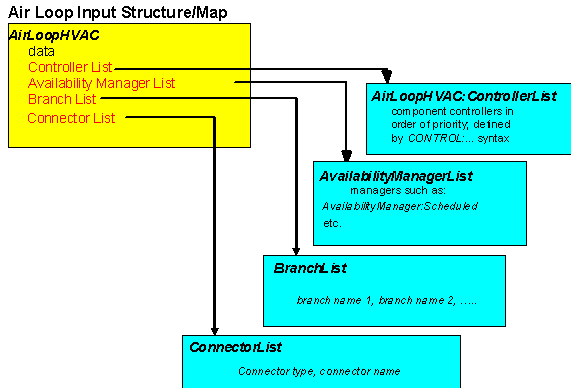

AvailabilityManagerAssignmentList

AirLoopHVAC:OutdoorAirSystem:EquipmentList

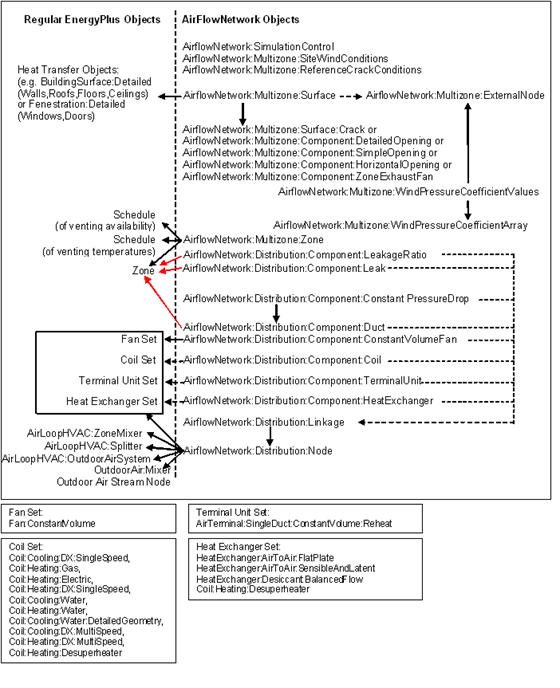

What the Airflow Network Model Can and Cannot Do

AirflowNetwork:SimulationControl

AirflowNetwork:Multizone:Surface

AirflowNetwork:MultiZone:ReferenceCrackConditions

AirflowNetwork:MultiZone:Surface:Crack

AirflowNetwork:MultiZone:Surface:EffectiveLeakageArea

AirflowNetwork:MultiZone:Component:DetailedOpening

AirflowNetwork:MultiZone:Component:HorizontalOpening

AirflowNetwork:MultiZone:Component:SimpleOpening

AirflowNetwork:MultiZone:Component:ZoneExhaustFan

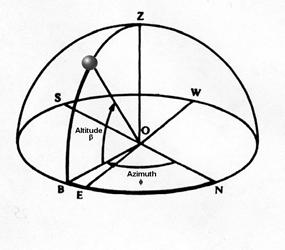

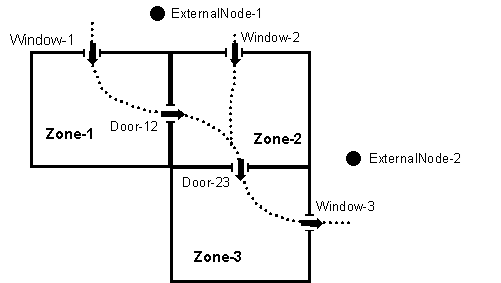

AirflowNetwork:MultiZone:ExternalNode

AirflowNetwork:MultiZone:WindPressureCoefficientArray

AirflowNetwork:MultiZone:WindPressureCoefficientValues

AirflowNetwork:Distribution:Node

AirflowNetwork:Distribution:Component:Leak

AirflowNetwork:Distribution:Component:LeakageRatio

AirflowNetwork:Distribution:Component:Duct

AirflowNetwork:Distribution:Component:ConstantVolumeFan

AirflowNetwork:Distribution:Component:Coil

AirflowNetwork:Distribution:Component:HeatExchanger

AirflowNetwork:Distribution:Component:TerminalUnit

AirflowNetwork:Distribution:Component:ConstantPressureDrop

AirflowNetwork:Distribution:Linkage

Group – Air Distribution Equipment

AirTerminal:SingleDuct:Uncontrolled

AirTerminal:SingleDuct:Uncontrolled Outputs

AirTerminal:SingleDuct:ConstantVolume:Reheat

AirTerminal:SingleDuct:ConstantVolume:Reheat Outputs

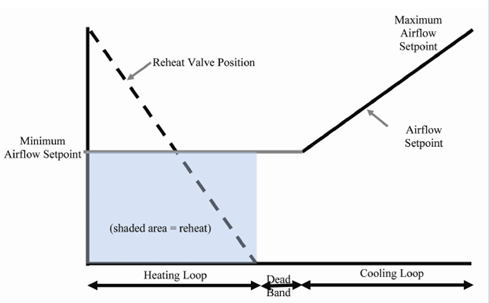

AirTerminal:SingleDuct:VAV:Reheat

AirTerminal:SingleDuct:VAV:Reheat Outputs

AirTerminal:SingleDuct:VAV:Reheat:VariableSpeedFan

AirTerminal:SingleDuct:VAV:Reheat:VariableSpeedFan Outputs

AirTerminal:SingleDuct:VAV:HeatAndCool:Reheat

AirTerminal:SingleDuct:VAV:HeatAndCool:Reheat Outputs

AirTerminal:SingleDuct:VAV:NoReheat

AirTerminal:SingleDuct:VAV:NoReheat Outputs

AirTerminal:SingleDuct:VAV:HeatAndCool:NoReheat

AirTerminal:SingleDuct:VAV:HeatAndCool:NoReheat Outputs

AirTerminal:SingleDuct:SeriesPIU:Reheat

AirTerminal:SingleDuct:SeriesPIU:Reheat Outputs

AirTerminal:SingleDuct:ParallelPIU:Reheat

AirTerminal:SingleDuct:ParallelPIU:Reheat Outputs

AirTerminal:SingleDuct:ConstantVolume:FourPipeInduction

AirTerminal:SingleDuct:ConstantVolume:FourPipeInduction Outputs

AirTerminal:SingleDuct:ConstantVolume:CooledBeam

AirTerminal:SingleDuct:ConstantVolume:CooledBeam Outputs

AirTerminal:DualDuct:ConstantVolume

AirTerminal:DualDuct:ConstantVolume Outputs

AirTerminal:DualDuct:VAV Outputs

AirTerminal:DualDuct:VAV:OutdoorAir

AirTerminal:DualDuct:VAV:OutdoorAir Outputs

ZoneHVAC:IdealLoadsAirSystem Outputs

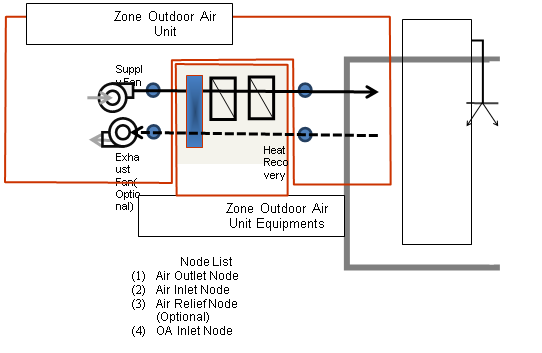

ZoneHVAC:OutdoorAirUnit Outputs

ZoneHVAC:OutdoorAirUnit:EquipmentList

ZoneHVAC:WindowAirConditioner Outputs

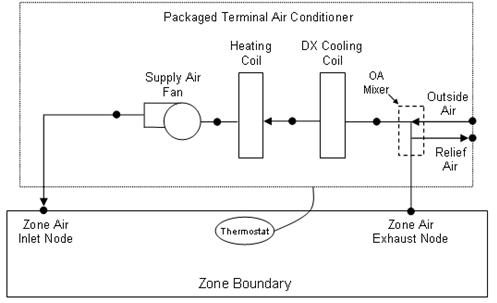

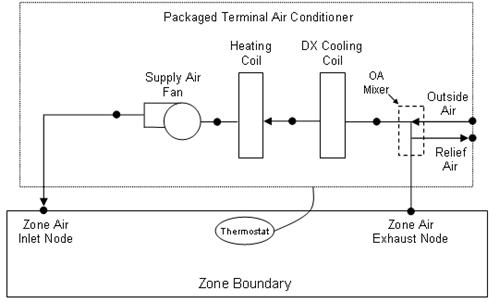

ZoneHVAC:PackagedTerminalAirConditioner

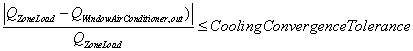

ZoneHVAC:PackagedTerminalAirConditioner Outputs

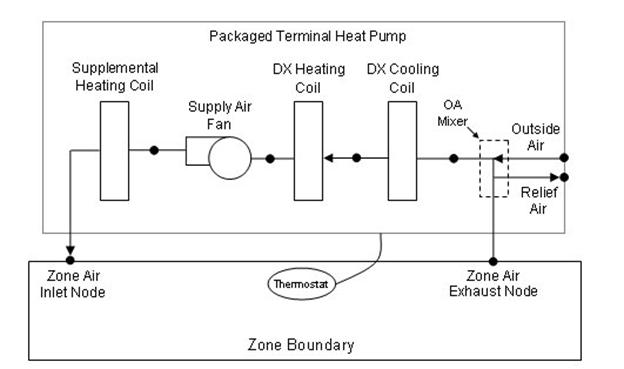

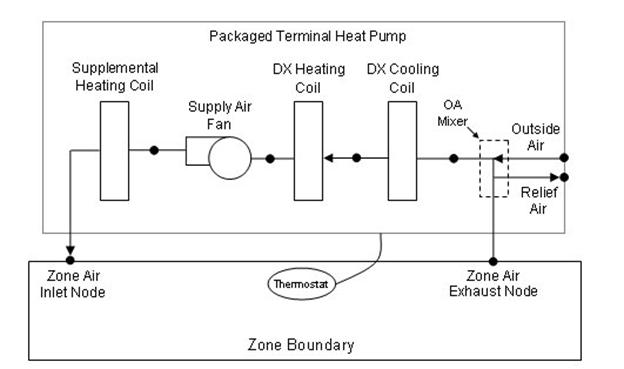

ZoneHVAC:PackagedTerminalHeatPump

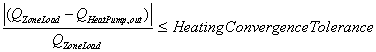

ZoneHVAC:PackagedTerminalHeatPump Outputs

ZoneHVAC:RefrigerationChillerSet

ZoneHVAC:WaterToAirHeatPump Outputs

ZoneHVAC:Dehumidifier:DX Outputs

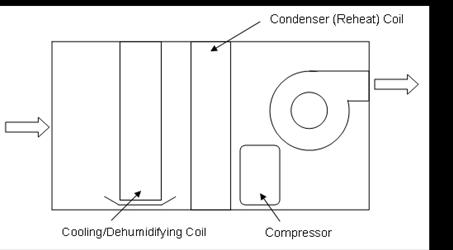

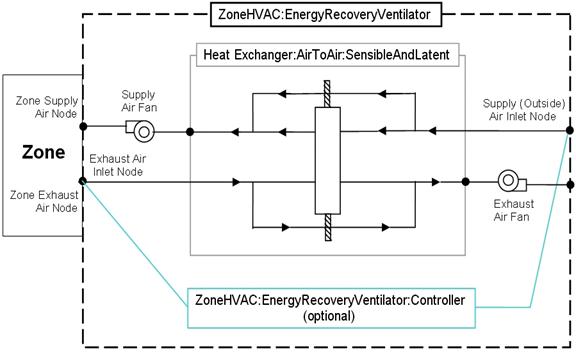

ZoneHVAC:EnergyRecoveryVentilator

ZoneHVAC:EnergyRecoveryVentilator Outputs

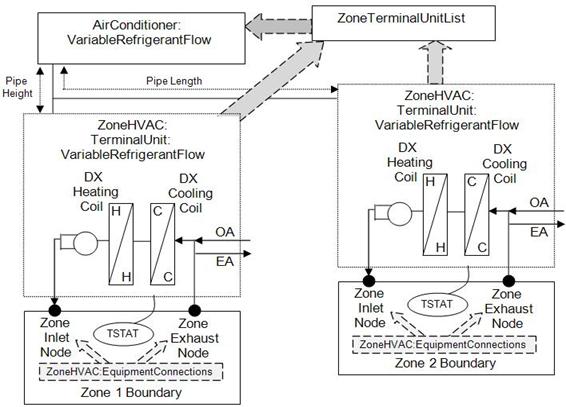

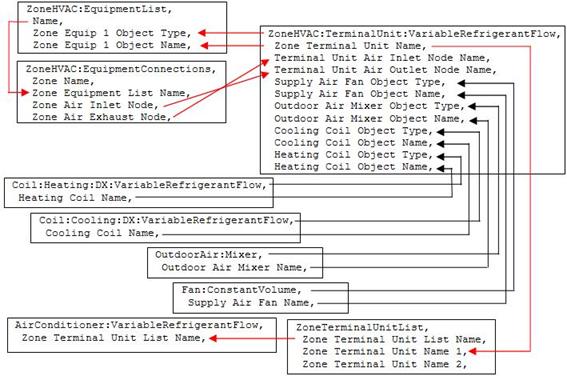

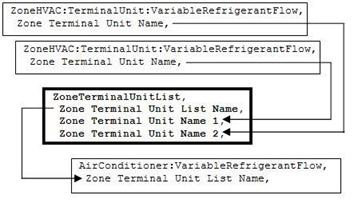

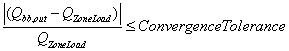

ZoneHVAC:TerminalUnit:VariableRefrigerantFlow

ZoneHVAC:TerminalUnit:VariableRefrigerantFlow Outputs

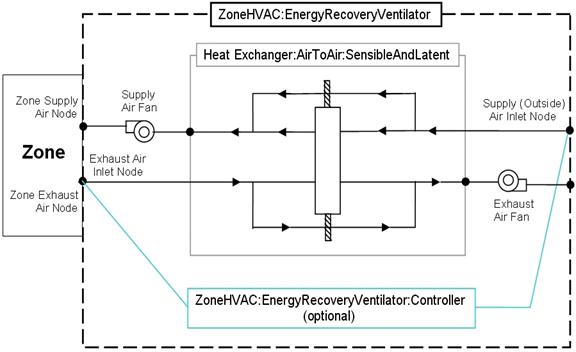

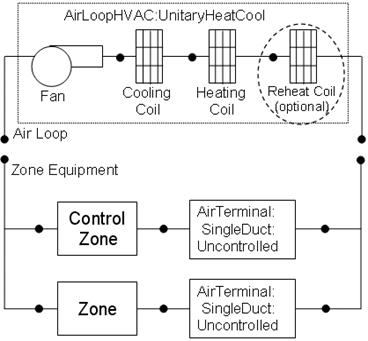

AirLoopHVAC:Unitary:Furnace:HeatCool

AirLoopHVAC:Unitary:Furnace:HeatCool Outputs

AirLoopHVAC:UnitaryHeatCool Outputs

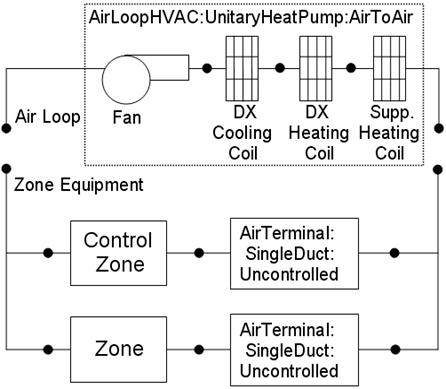

AirLoopHVAC:UnitaryHeatPump:AirToAir

AirLoopHVAC:UnitaryHeatPump:AirToAir Outputs

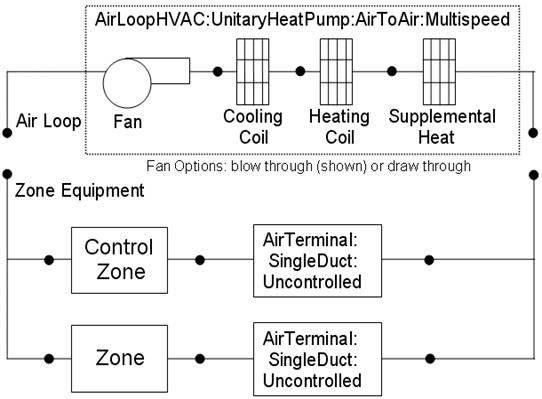

AirLoopHVAC:UnitaryHeatPump:AirToAir:MultiSpeed

AirLoopHVAC:UnitaryHeatPump:AirToAir:MultiSpeed Outputs

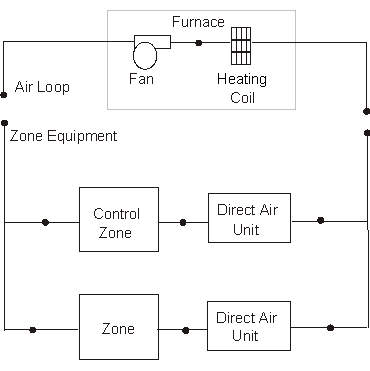

AirLoopHVAC:Unitary:Furnace:HeatOnly

AirLoopHVAC:Unitary:Furnace:HeatOnly Outputs

AirLoopHVAC:UnitaryHeatOnly Outputs

AirLoopHVAC:UnitaryHeatPump:WaterToAir

AirLoopHVAC:UnitaryHeatPump:WaterToAir Outputs

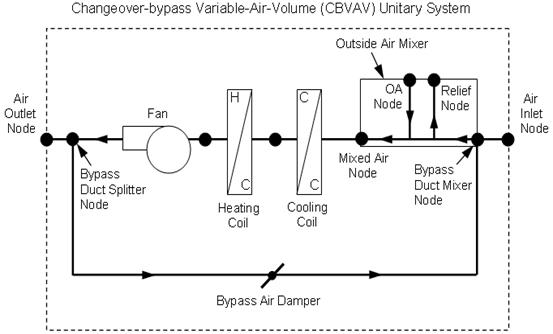

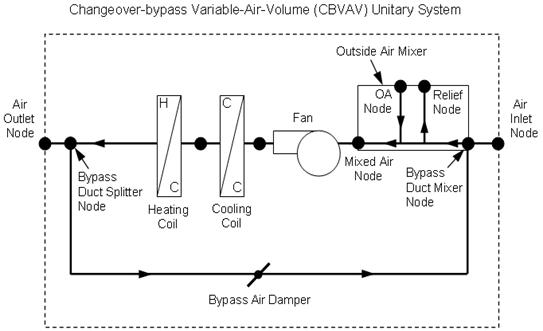

AirLoopHVAC:UnitaryHeatCool:VAVChangeoverBypass

AirLoopHVAC:UnitaryHeatCool:VAVChangeoverBypass Outputs

AirLoopHVAC:UnitaryCoolOnly Outputs

Group – Variable Refrigerant Flow Equipment

AirConditioner:VariableRefrigerantFlow

AirConditioner:VariableRefrigerantFlow Outputs

Group – Radiative / Convective Units

ZoneHVAC:Baseboard:RadiantConvective:Water

ZoneHVAC:Baseboard:RadiantConvective:Water Outputs

ZoneHVAC:Baseboard:RadiantConvective:Steam

ZoneHVAC:Baseboard:RadiantConvective:Steam Outputs

ZoneHVAC:Baseboard:RadiantConvective:Electric

ZoneHVAC:Baseboard:RadiantConvective:Electric Outputs

ZoneHVAC:Baseboard:Convective:Water

ZoneHVAC:Baseboard:Convective:Water Outputs

ZoneHVAC:Baseboard:Convective:Electric

ZoneHVAC:Baseboard:Convective:Electric Outputs

ZoneHVAC:LowTemperatureRadiant:VariableFlow

ZoneHVAC:LowTemperatureRadiant:VariableFlow Outputs

ZoneHVAC:LowTemperatureRadiant:ConstantFlow

ZoneHVAC:LowTemperatureRadiant:ConstantFlow Outputs

ZoneHVAC:LowTemperatureRadiant:Electric

ZoneHVAC:LowTemperatureRadiant:Electric Outputs

ZoneHVAC:LowTemperatureRadiant:SurfaceGroup

ZoneHVAC:HighTemperatureRadiant

ZoneHVAC:HighTemperatureRadiant Outputs

ZoneHVAC:VentilatedSlab Outputs

ZoneHVAC:VentilatedSlab:SlabGroup

Refrigeration Compressor Rack Outputs

Refrigeration:CaseAndWalkInList

Refrigeration:Compressor Outputs

Refrigeration:Subcooler Outputs

Refrigeration:Condenser:AirCooled

Refrigeration:Condenser:AirCooled Outputs

Refrigeration:Condenser:EvaporativeCooled

Refrigeration:Condenser:EvaporativeCooled Outputs

Refrigeration:Condenser:WaterCooled

Refrigeration:Condenser:WaterCooled Outputs

Refrigeration:Condenser:Cascade

Refrigeration:Condenser:Cascade Outputs

Refrigeration:TransferLoadList

Refrigeration:SecondarySystem Outputs

Additional Refrigeration Outputs Available for Each Zone

Additional Refrigeration Outputs for Each Zone

Refrigeration:AirChiller Outputs

Group – Zone Controls – Thermostats and Humidistats

ZoneControl:Thermostat Outputs

ThermostatSetpoint:SingleHeating

ThermostatSetpoint:SingleCooling

ThermostatSetpoint:SingleHeatingOrCooling

ThermostatSetpoint:DualSetpoint

ZoneControl:Thermostat:OperativeTemperature

Zone Control Themostatic Operative Temperature Outputs

ZoneControl:Thermostat:TemperatureAndHumidity

ZoneControl:Humidistat Outputs

ZoneControl:Thermostat:ThermalComfort

ZoneControl:Thermostat:ThermalComfort Outputs

ThermostatSetpoint:ThermalComfort:Fanger:SingleHeating

ThermostatSetpoint:ThermalComfort:Fanger:SingleCooling

ThermostatSetpoint:ThermalComfort:Fanger:SingleHeatingOrCooling

ThermostatSetpoint:ThermalComfort:Fanger:DualSetpoint

ZoneControl:ContaminantController

ZoneControl:ContaminantController Outputs

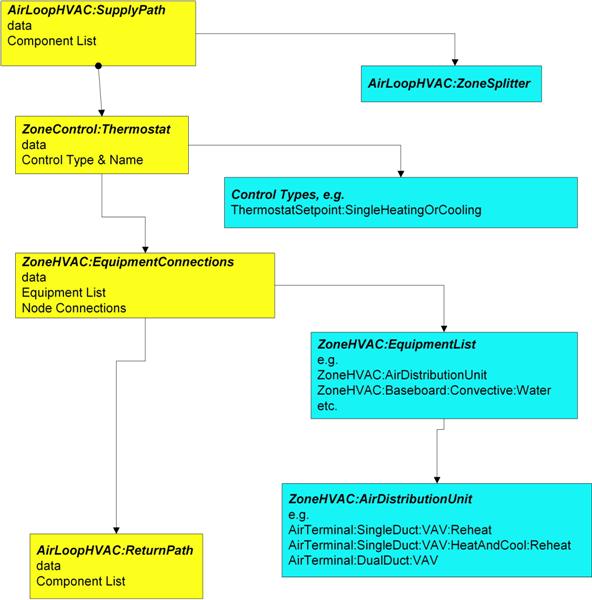

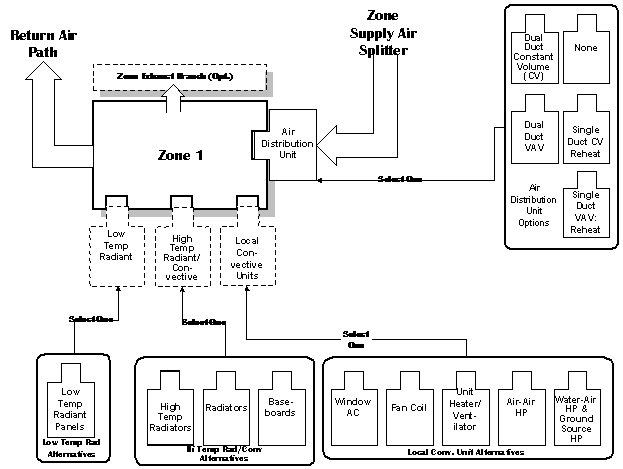

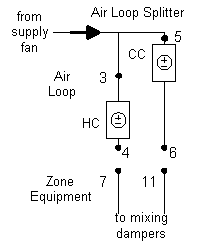

AirLoopHVAC:SupplyPath, AirLoopHVAC:ReturnPath

SolarCollector:FlatPlate:Water

SolarCollector:FlatPlate:Water Output

SolarCollectorPerformance:FlatPlate

SolarCollectorPerformance:FlatPlate Output

SolarCollector:FlatPlate:PhotovoltaicThermal

SolarCollector:FlatPlate:PhotovoltaicThermal Outputs

SolarCollectorPerformance:PhotovoltaicThermal:Simple

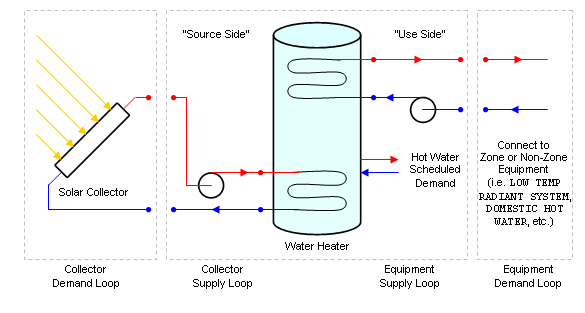

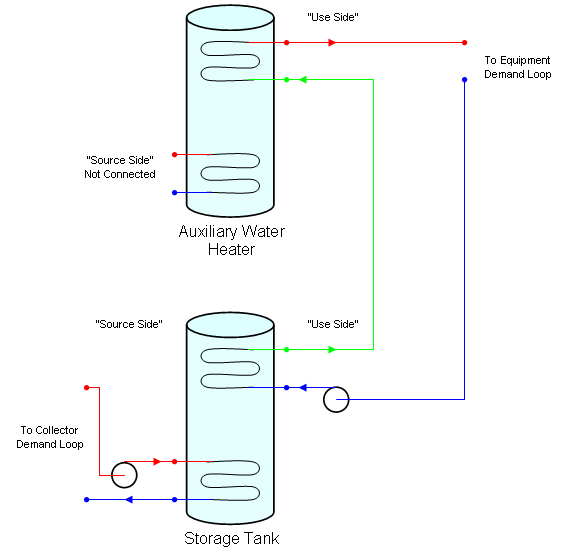

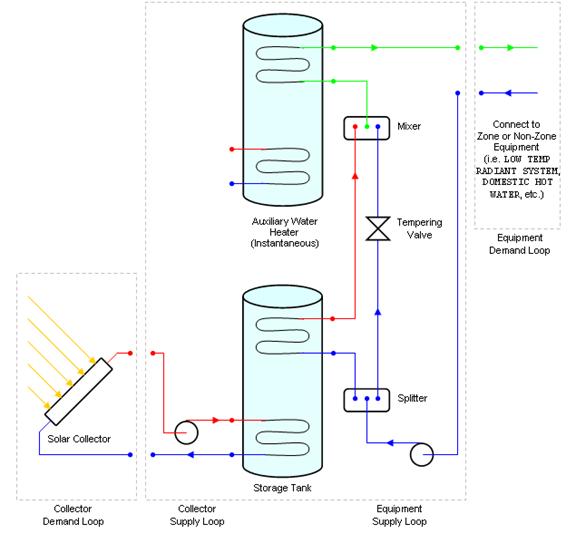

Solar Collector Heating System Plant Connections

SolarCollector:UnglazedTranspired

SolarCollector:UnglazedTranspired Outputs

SolarCollector:UnglazedTranspired:MultiSystem

Pump:VariableSpeed:Condensate Outputs

HeaderedPumps:ConstantSpeed Outputs

HeaderedPumps:VariableSpeed Outputs

Group – Heating and Cooling Coils

Coil:Heating:Desuperheater Outputs

Coil:DX:CoolingEmpirical:VariableRefrigerantFlow

Coil:Cooling:DX:VariableRefrigerantFlow Outputs

Coil:DX:HeatingEmpirical:VariableRefrigerantFlow

Coil:Heating:DX:VariableRefrigerantFlow Outputs

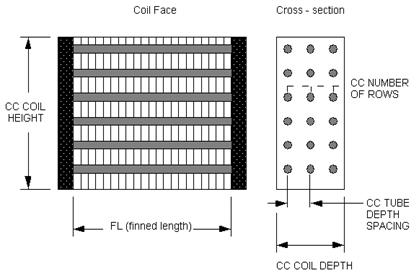

Coil:Cooling:Water:DetailedGeometry

Coil:Cooling:Water:DetailedGeometry Outputs

Coil:Cooling:DX:TwoStageWithHumidityControlMode

Coil:Cooling:DX:MultiSpeed Outputs

Coil:Heating:DX:MultiSpeed Outputs

Coil:WaterHeating:Desuperheater

Coil:WaterHeating:Desuperheater Outputs

CoilSystem:Cooling:DX:HeatExchangerAssisted

CoilSystem:Cooling:DX:HeatExchangerAssisted Outputs

CoilSystem:Cooling:Water:HeatExchangerAssisted

CoilSystem:Cooling:Water:HeatExchangerAssisted Outputs

Coil:WaterHeating:AirToWaterHeatPump

Coil:WaterHeating:AirToWaterHeatPump Outputs

Coil:Cooling:WaterToAirHeatPump:ParameterEstimation

Coil:Cooling:WaterToAirHeatPump:EquationFit

Water to Air Heat Pump Cooling Coil (Parameter Estimation and Equation Fit) Outputs

Coil:Heating:WaterToAirHeatPump:ParameterEstimation

Coil:Heating:WaterToAirHeatPump:EquationFit

Water to Air Heat Pump Heating Coil (parameter Estimation and Equation Fit) Outputs

FanPerformance:NightVentilation

Humidfier:Steam:Electric Outputs

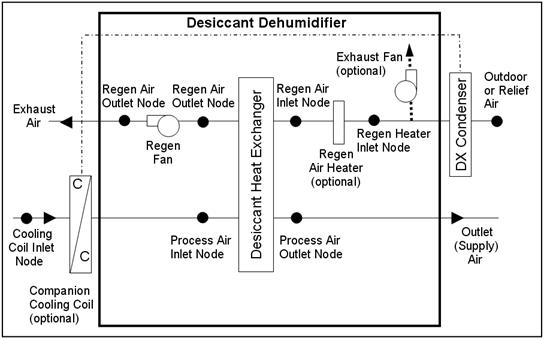

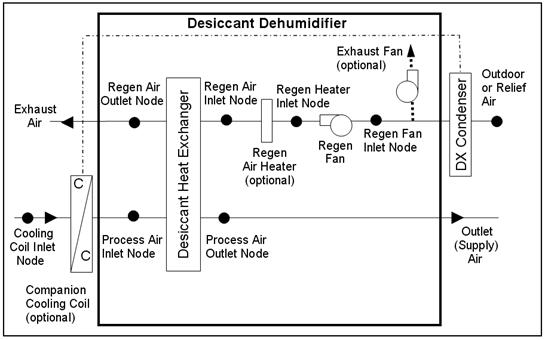

Group – Desiccant Dehumidifiers

Dehumidifier:Desiccant:NoFans Outputs

Desiccant Dehumidifier Outputs

Group – Energy Management System (EMS)

EnergyManagementSystem:Actuator

EnergyManagementSystem:ProgramCallingManager

EnergyManagementSystem:Program

EnergyManagementSystem:Subroutine

EnergyManagementSystem:GlobalVariable

EnergyManagementSystem:OutputVariable

EnergyManagementSystem:TrendVariable

EnergyManagementSystem:InternalVariable

Group – System Availability Managers

AvailabilityManager:ScheduledOn

AvailabilityManager:ScheduledOn Outputs

AvailabilityManager:ScheduledOff

AvailabilityManager:ScheduledOff Outputs

AvailabilityManager:NightCycle Outputs

AvailabilityManager:DifferentialThermostat

AvailabilityManager:DifferentialThermostat Outputs

AvailabilityManager:HighTemperatureTurnOff

AvailabilityManager:HighTemperatureTurnOff Outputs

AvailabilityManager:HighTemperatureTurnOn

AvailabilityManager:HighTemperatureTurnOn Outputs

AvailabilityManager:LowTemperatureTurnOff

AvailabilityManager:LowTemperatureTurnOff Outputs

AvailabilityManager:LowTemperatureTurnOn

AvailabilityManager:LowTemperatureTurnOn Outputs

System Availability Manager:Night Ventilation

AvailabilityManager:NightVentilation Outputs

AvailabilityManager:HybridVentilation

AvailabilityManager:HybridVentilation Outputs

SetpointManager:Scheduled:DualSetpoint

SetpointManager:OutdoorAirReset

SetpointManager:SingleZone:Reheat

SetpointManager:SingleZone:Heating

SetpointManager:SingleZone:Cooling

SetpointManager:SingleZone:Humidity:Minimum

SetpointManager:SingleZone:Humidity:Maximum

SetpointManager:OutdoorAirPretreat

SetpointManager:ReturnAirBypassFlow

SetpointManager:WarmestTemperatureFlow

SetpointManager:MultiZone:Cooling:Average

SetpointManager:MultiZone:Heating:Average

SetpointManager:MultiZone:MinimumHumidity:Average

SetpointManager:MultiZone:MaximumHumidity:Average

SetpointManager:MultiZone:Humidity:Minimum

SetpointManager:MultiZone:Humidity:Maximum

SetpointManager:FollowOutdoorAirTemperature

SetpointManager:FollowSystemNodeTemperature

SetpointManager:FollowGroundTemperature

Controls (Air Loop and Zone Equipment)

Controller:MechanicalVentilation

ZoneHVAC:EnergyRecoveryVentilator:Controller

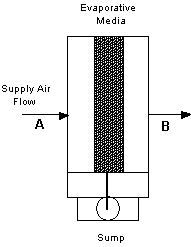

EvaporativeCooler:Direct:CelDekPad

EvaporativeCooler:Direct:CelDekPad Outputs

EvaporativeCooler:Direct:ResearchSpecial

EvaporativeCooler:Direct:ResearchSpecial Outputs

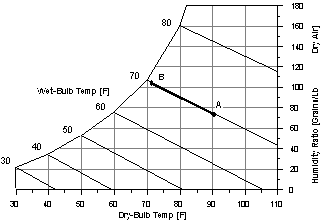

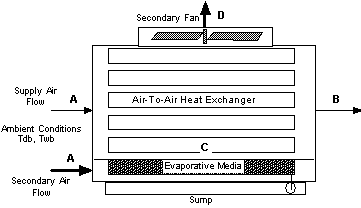

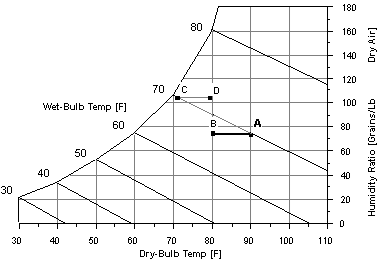

EvaporativeCooler:Indirect:CelDekPad

EvaporativeCooler:Indirect:CelDekPad Outputs

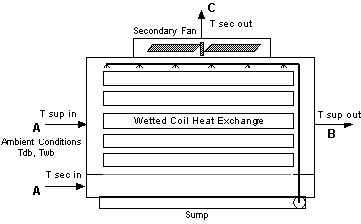

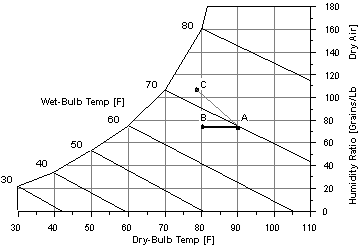

EvaporativeCooler:Indirect:WetCoil

EvaporativeCooler:Indirect:WetCoil Outputs

EvaporativeCooler:Indirect:ResearchSpecial

EvaporativeCooler:Indirect:ResearchSpecial Outputs

HeatExchanger:AirToAir:FlatPlate

HeatExchanger:AirToAir:FlatPlate Outputs

HeatExchanger:AirToAir:SensibleAndLatent

HeatExchanger:AirToAir:SensibleAndLatent Outputs

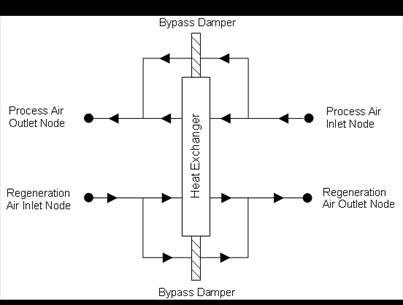

HeatExchanger:Desiccant:BalancedFlow

HeatExchanger:Desiccant:BalancedFlow Outputs

HeatExchanger:Desiccant:BalancedFlow:PerformanceDataType1

HeatExchanger:Desiccant:BalancedFlow:PerformanceDataType1 Outputs

Group – Demand Limiting Controls

DemandManagerAssignmentList Outputs

DemandManager:ExteriorLights Outputs

DemandManager:ElectricEquipment

DemandManager:ElectricEquipment Outputs

DemandManager:Thermostats Outputs

Group -- Electric Load Center-Generator Specifications

ElectricLoadCenter:Transformer

ElectricLoadCenter:Transformer Outputs

ElectricLoadCenter:Distribution

ElectricLoadCenter:Distribution Outputs

ElectricLoadCenter:Generators Outputs

ElectricLoadCenter:Inverter:Simple

ElectricLoadCenter:Inverter:FunctionOfPower

ElectricLoadCenter:Inverter:LookUpTable

ElectricLoadCenter:Storage:Simple

ElectricLoadCenter:Storage:Simple Outputs

ElectricLoadCenter:Storage: Battery

ElectricLoadCenter: Storage:Battery Outputs

Generator:InternalCombustionEngine

Generator:InternalCombustionEngine Outputs

Generator:CombustionTurbine Outputs

Generator:MicroTurbine Outputs

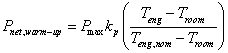

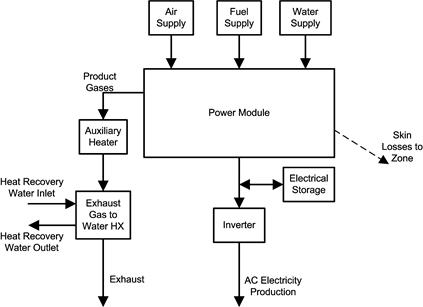

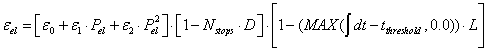

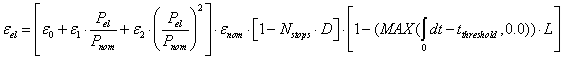

Generator:MicroCHP:NonNormalizedParameters

Generator:FuelCell:PowerModule

Generator:FuelCell:StackCooler

Generator:FuelCell:WaterSupply

Generator:FuelCell:AuxiliaryHeater

Generator:FuelCell:ElectricalStorage

Generator:Photovoltaic Outputs

PhotovoltaicPerformance:Simple

PhotovoltaicPerformance:EquivalentOne-Diode

PhotovoltaicPerformance:Sandia

Generator:WindTurbine Outputs:

WaterUse:RainCollector Outputs

FluidProperties:GlycolConcentration

HVACTemplate:Zone:IdealLoadsAirSystem

HVACTemplate:Zone:VAV:FanPowered

HVACTemplate:Zone:WaterToAirHeatPump

HVACTemplate:System:UnitaryHeatPump:AirToAir

HVACTemplate:System:PackagedVAV

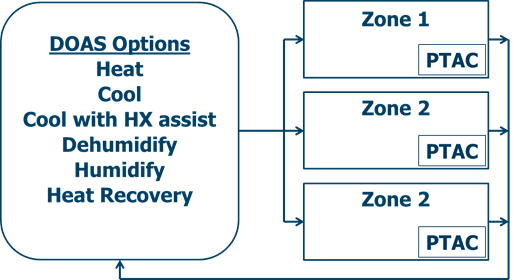

HVACTemplate:System:DedicatedOutdoorAir

HVACTemplate:Plant:ChilledWaterLoop

HVACTemplate:Plant:HotWaterLoop

HVACTemplate:Plant:MixedWaterLoop

Conceptual Framework – Variables and Hierarchy

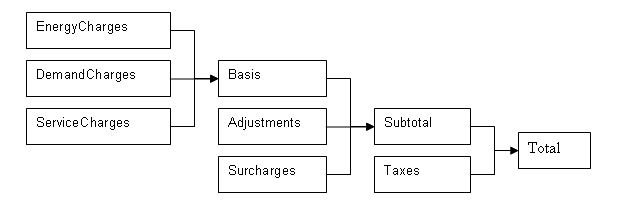

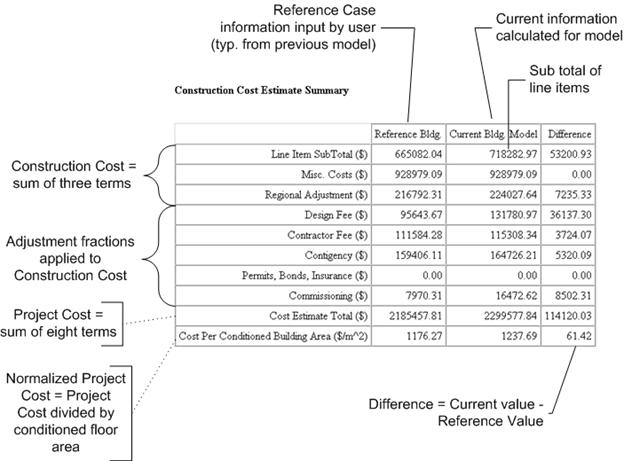

Economic Results Summary Report

Economics Cost Estimate Reporting

LifeCycleCost:NonrecurringCost

LifeCycleCost:UsePriceEscalation

OutputControl:SurfaceColorScheme

OutputControl:ReportingTolerances

Output:Meter and Output:Meter:MeterFileOnly

Output:Meter:Cumulative and Output:Meter:Cumulative:MeterFileOnly

Output:EnvironmentalImpactFactors

Environmental Pollution Impact Outputs

Creating Charts and Spreadsheet files from Output Variables

Predefined Annual Summary Reports

Predefined Monthly Summary Reports

Weather Data Hourly Interpolation

Weather File Data Reporting (errors) during Simulation

Appendix A. Units and Abbreviations

Standard EnergyPlus Conditions

Standard Temperature and Pressure

This document is intended to be an encyclopedic reference for the EnergyPlus Input Data Dictionary (IDD), Input Data File (IDF) and potential resultant outputs (various output files).

The following descriptions are “grouped” by the elements in the IDD (ref: Getting Started Document and the IDD Conventions). In some cases, the descriptions of reporting will be done for an object (e.g. Lighting electrical consumption or thermal comfort value for a group of people) and in some cases for the entire group (e.g., ambient condition reports).

The usual procedure for non-interactive programs is to process all the input necessary to “do the job”, perform the actions required by the input, and somewhere along the way produce reports on the actions. Usually, there will be error messages on incorrect input statements and/or incorrect conditions detected during processing. Usually, the input is echoed in its entirety so that the context of errors is shown clearly.

Results are typically output into reports as well as a compilation of various inputs reformatted into different groupings than were originally entered (defaults filled in, etc.)

EnergyPlus does all the above. However, some nuances are different from the usual actions.

1) EnergyPlus reads the data dictionary (Energy+.idd) and the input data file (in.idf) prior to doing anything else. Only after this is done does processing start. HOWEVER, the input processor only knows as much as the data dictionary has told it. It knows which fields should be alpha and which should be numeric. All of this information (including the IDD) is echoed to the audit file (audit.out) in case errors occur. Most of the errors show up (out of context) in the standard error file (eplusout.err) – there might be enough information to decipher where the error is or you may have to look at the more inclusive audit file. Invalid numeric fields are detected during this processing and default numeric fields are filled. For more information on the IDD, its structure and implications, please see the IDD Conventions discussion below.

2) The biggest difference between EnergyPlus and more traditional input processing is that EnergyPlus is modular in its actual filling in the details for the simulation. Because of the modular structure of EnergyPlus, each module is responsible for “getting” its own input. It receives this input from the input processor in the form of alpha and numeric fields. Each module typically gets all its input the first time it is called. The implication for the user is that error messages may show up in somewhat peculiar places. A further implication is that no order is needed in the input data file! Data that is not needed by a particular simulation is not processed.

3) The data dictionary has the capability to do “automatic” range checking on numeric fields as well as fill in numeric defaults. Both filling in defaults and “automatic” range checking are done when the data is read. Other checks may need a combination of fields and won’t be done until the data is “processed” (after the simulation starts).

4) A couple of other differences that might not be true in other programs: Blanks are significant in alpha fields SO DesignDay is not the same as Design Day (1 space between Design and Day) nor Design Day (2 spaces between Design and Day). Alpha objects, however, are case insensitive SO DesignDay is the same as ‘designday’ or ‘SizingPeriod:DesignDay’.

1) Unlike the usual formatted output text formatted reports, EnergyPlus usual output is either at the summary or at the detailed (variable) level. Summary reports exist for many inputs as well as sizing results. The more detailed variable level reporting is produced as “stream of consciousness” (as the simulation happens) and must be post-processed for more sensible viewing.

2) Most EnergyPlus reporting can be readily viewed in current spreadsheet programs – or other software that can process “delimited variable” reports. In these kind of reports, each “column” is separated from the next by a “delimiter”. Typical delimiters are “comma” and “tab”. Gradually, EnergyPlus reporting is moving from all comma separated reports to allow the user to select the delimiter via “style” objects.

3) Styled reports allow for more selectable output reporting but also increase the number of output files as we have chosen to create the report names with extensions that typify the actual reporting. Depending on the reporting, these can be:

ü Tab – reports with a .tab extension have tabs as the delimiter. These report files (directly from EnergyPlus) will be named something like “eplus<xxx>.tab” where the <xxx> is a short name of the kind of report (e.g. Zsz for Zone Sizing, Map for Daylighting Map)

ü Csv – reports with a .csv extension have commas as the delimiter. These are also specially formatted for use in spreadsheets (such as the compilation of results from the eplusout.eso file into the eplusout.csv file using the default post-processor program).

ü Txt – reports with a .txt extension have spaces as the “delimiter” but only certain of these are really formatted the way you might expect: where multiple spaces make printing with a non-proportional font would produce readable output.

ü Html – reports with a .html extension are “web-browser” ready.

The following is a basic description of the structure of the IDD (it’s actually taken directly from the IDD file). As noted within, ! signifies a comment character as does the \. \ has also been adopted as a convention for including more specific comments about each field in an object. These have been used with success in the IDFEditor and it is hoped the flexibility will provide other interface developers with useful information.

!IDD_Version VERSION NUMBER

! **************************************************************************

! This file is the Input Data Dictionary (IDD) for EnergyPlus.

! The IDD defines the syntax and data model for each type of input "Object."

! Lines in EnergyPlus input files (and IDD) are limited to 500 characters.

!

! Object Description

! ------------------

! To define an object (a record with data), develop a key word that is unique

! Each data item to the object can be A (Alphanumeric string) or N (numeric)

! Number each A and N. This will show how the data items will be put into the

! arrays that are passed to the Input Processor "Get" (GetObjectItem) routines.

! All alpha fields are limited to 100 characters. Numeric fields should be

! valid numerics (can include such as 1.0E+05) and are placed into double

! precision variables.

!

! NOTE: Even though a field may be optional, a comma representing that field

! must be included (unless it is the last field in the object). Since the

! entire input is "field-oriented" and not "keyword-oriented", the EnergyPlus

! Input Processor must have some representation (even if blank) for each

! field.

!

! Object Documentation

! --------------------

! In addition, the following special comments appear one per line and

! most are followed by a value. Comments may apply to a field or the object

! or a group of objects.

!

! Field-level comments:

!

! \field Name of field

! (should be succinct and readable, blanks are encouraged)

!

! \note Note describing the field and its valid values

!

! \required-field To flag fields which may not be left blank

! (this comment has no "value")

!

! \begin-extensible Marks the first field at which the object accepts an extensible

! field set. A fixed number of fields from this marker define the

! extensible field set, see the object code \extensible for

! more information.

!

! \units Units (must be from EnergyPlus standard units list)

! EnergyPlus units are standard SI units

!

! \ip-units IP-Units (for use by input processors with IP units)

! This is only used if the default conversion is not

! appropriate.

!

! \unitsBasedOnField For fields that may have multiple possible units, indicates

! the field in the object that can be used to determine

! the units. The field reference is in the A2 form.

!

! \minimum Minimum that includes the following value

!

! \minimum> Minimum that must be > than the following value

!

! \maximum Maximum that includes the following value

!

! \maximum< Maximum that must be < than the following value

!

! \default Default for the field (if N/A then omit entire line)

!

! \deprecated This field is not really used and will be deleted from the object.

! The information is gotten internally within the program.

!

! \autosizable Flag to indicate that this field can be used with the Auto

! Sizing routines to produce calculated results for the

! field. If a value follows this, then that will be used

! when the "Autosize" feature is flagged. To trigger

! autosizing for a field, enter Autosize as the field's

! value. Only applicable to numeric fields.

!

! \autocalculatable Flag to indicate that this field can be automatically

! calculated. To trigger auto calculation for a field, enter

! Autocalculate as the field's value. Only applicable to

! numeric fields.

!

! \type Type of data for the field -

! integer

! real

! alpha (arbitrary string),

! choice (alpha with specific list of choices, see

! \key)

! object-list (link to a list of objects defined elsewhere,

! see \object-list and \reference)

! node (name used in connecting HVAC components)

!

! \retaincase Retains the alphabetic case for alpha type fields

!

! \key Possible value for "\type choice" (blanks are significant)

! use multiple \key lines to indicate all valid choices

!

! \object-list Name of a list of user-provided object names that are valid

! entries for this field (used with "\reference")

! see Zone and BuildingSurface:Detailed objects below for

! examples.

! ** Note that a field may have multiple \object-list commands.

!

! \reference Name of a list of names to which this object belongs

! used with "\type object-list" and with "\object-list"

! see Zone and BuildingSurface:Detailed objects below for

! examples:

!

! Zone,

! A1 , \field Name

! \type alpha

! \reference ZoneNames

!

! BuildingSurface:Detailed,

! A4 , \field Zone Name

! \note Zone the surface is a part of

! \type object-list

! \object-list ZoneNames

!

! For each zone, the field "Name" may be referenced

! by other objects, such as BuildingSurface:Detailed, so it is

! commented with "\reference ZoneNames"

! Fields that reference a zone name, such as BuildingSurface:Detailed's

! "Zone Name", are commented as

! "\type object-list" and "\object-list ZoneNames"

! ** Note that a field may have multiple \reference commands.

! ** This is useful if the object belongs to a small specific

! object-list as well as a larger more general object-list.

!

! Object-level comments:

!

! \memo Memo describing the object

!

! \unique-object To flag objects which should appear only once in an idf

! (this comment has no "value")

!

! \required-object To flag objects which are required in every idf

! (this comment has no "value")

!

! \min-fields Minimum number of fields that should be included in the

! object. If appropriate, the Input Processor will fill

! any missing fields with defaults (for numeric fields).

! It will also supply that number of fields to the "get"

! routines using blanks for alpha fields (note -- blanks

! may not be allowable for some alpha fields).

!

! \obsolete This object has been replaced though is kept (and is read)

! in the current version. Please refer to documentation as

! to the dispersal of the object. If this object is

! encountered in an IDF, the InputProcessor will post an

! appropriate message to the error file.

! usage: \obsolete New=>[New object name]

!

! \extensible:<#> This object is dynamically extensible -- meaning, if you

! change the IDD appropriately (if the object has a simple list

! structure -- just add items to the list arguments (i.e. BRANCH

! LIST). These will be automatically redimensioned and used during

! the simulation. <#> should be entered by the developer to signify

! how many of the last fields are needed to be extended (and EnergyPlus

! will attempt to auto-extend the object). The first field of the first

! instance of the extensible field set is marked with \begin-extensible.

!

! \begin-extensible See previous item, marks beginning of extensible fields in

! an object.

!

! \format The object should have a special format when saved in

! the IDF Editor with the special format option enabled.

! The options include SingleLine, Vertices, CompactSchedule,

! FluidProperties, ViewFactors, and Spectral.

! The SingleLine option puts all the fields for the object

! on a single line. The Vertices option is used in objects

! that use X, Y and Z fields to format those three fields

! on a single line.

! The CompactSchedule formats that specific object.

! The FluidProperty option formats long lists of fluid

! properties to ten values per line.

! The ViewFactor option formats three fields related to

! view factors per line.

! The Spectral option formats the four fields related to

! window glass spectral data per line.

!

! \reference-class-name Adds the name of the class to the reference list

! similar to \reference.

!

! Group-level comments:

!

! \group Name for a group of related objects

!

!

! Notes on comments

! -----------------

!

! 1. If a particular comment is not applicable (such as units, or default)

! then simply omit the comment rather than indicating N/A.

!

! 2. Memos and notes should be brief (recommend 5 lines or less per block).

! More extensive explanations are expected to be in the user documentation

In addition, the IDD contains indications of IP (inch-pound) units for the EnergyPlus standard SI (Systems International) units. These may be used by input and output interfaces to display values in the IP system. As noted, if the IP units are “standard” (first block below), then no \ip-units is expected in the field. Note that for some fields – due to their multiple use (for example, schedule values) – there cannot be a ip-unit designation.

! Default IP conversions (no \ip-units necessary)

! m => ft 3.281

! W => Btu/h 3.412

! m3/s => ft3/min 2118.6438

! C => F 1.8 (plus 32)

! kg/J => lb/Btu 2325.83774250441

! Pa => psi 0.0001450377

! W/m-K => Btu-in/h-ft2-F 6.93481276005548

! W/K => Btu/h-F 1.8987

! deltaC => deltaF 1.8

! m2 => ft2 10.764961

! K => R 1.8

! 1/K => 1/R 0.555555556

! (kg/s)/W => (lbm/sec)/(Btu/hr) 0.646078115385742

! J/kg => Btu/lb 0.00042986 (plus 7.686)

! kg-H2O/kg-air => lb-H2O/lb-air 1

! kJ/kg => Btu/lb 0.429925

! lux => foot-candles 0.092902267

! kg/m3 => lb/ft3 0.062428

! kg/s => lb/s 2.2046

! kg/s-m => lb/s-ft 0.67194

! m3 => ft3 35.319837041

! m3 => gal 264.172

! W/m2-K => Btu/h-ft2-F 0.176110194261872

! 1/m => 1/ft 0.304785126485827

! J/kg-K => Btu/lb-F 0.000239005736137667

! J/m3-K => Btu/ft3-F 1.49237004739337E-05

! m/s => ft/min 196.86

! m/s => miles/hr 2.2369

! m2-K/W => ft2-F-hr/Btu 5.678263

! W/m2 => Btu/h-ft2 0.316957210776545

! A/K => A/F 0.555555555555556

! g/kg => grains/lb 7.00000

! g/m-s => lb/ft-s 0.000671968949659

! g/m-s-K => lb/ft-s-F 0.000373574867724868

! J/K => Btu/F 0.000526917584820558

! J/kg-K2 => Btu/lb-F2 0.000132889924714692

! J/m3 => Btu/ft3 2.68096514745308E-05

! kg/kg-K => lb/lb-F 0.555555555555556

! kPa => psi 0.145038

! kPa => inHg 0.29523

! m2/s => ft2/s 10.764961

! m3/kg => ft3/lb 16.018

! m3/m3 => ft3/ft3 1

! N-s/m2 => lbf-s/ft2 0.0208857913669065

! V/K => V/F 0.555555555555556

! W/m-K2 => Btu/h-F2-ft 0.321418310071648

! m3/s-m => ft3/min-ft 645.89

! J/m2-K => Btu/ft2-F 4.89224766847393E-05

! cycles/hr => cycles/hr 1

! kg/kg => lb/lb 1

! J/J => Btu/Btu 1

! g/GJ => lb/MWh 0.00793664091373665

! L/GJ => gal/kWh 0.000951022349025202

! m3/GJ => ft3/MWh 127.13292

! m3/s-m2 => ft3/min-ft2 196.85

! m3/s-person => ft3/min-person 2118.6438

! W/m2-K2 => Btu/h-ft2-F2 0.097826

! g/MJ => lb/MWh 7.93664091373665

! L/MJ => gal/kWh 0.951022349025202

! m3/MJ => ft3/kWh 127.13292

! W/W => Btuh/Btuh 1

! $/m2 => $/ft2 0.0928939733269818

! $ => $ 1

! $/kW => $/(kBtuh/h) 0.293083235638921

! $/m3 => $/ft3 0.0283127014102352

! years => years 1

! $/(W/K) => $/(Btu/h-F) 0.52667614683731

! $/(m3/s) => $/(ft3/min) 0.000472000059660808

! W/m => Btu/h-ft 1.04072

! K/m => F/ft 0.54861322767449

! W/s => W/s 1

! kmol => kmol 1

! J => Wh 0.000277777777777778

! GJ => ton-hrs 78.9889415481832

! kg/m2 => lb/ft2 0.204794053596664

! kg => lb 2.2046

! percent/K => percent/F 0.555555555555556

! kg/s2 => lb/s2 2.2046

! g/mol => lb/mol 0.0022046

! deltaJ/kg => deltaBtu/lb 0.0004299

! person/m2 => person/ft2 0.0928939733269818

! m2/person => ft2/person 10.764961

! W/person => Btu/h-person 3.412

! m3/person => ft3/person 35.319837041

! m3/hr-person => ft3/hr-person 35.319837041

! m3/m2 => ft3/ft2 3.281

! m3/hr-m2 => ft3/hr-ft2 3.281

! m3/hr => ft3/hr 35.319837041

! s/m => s/ft 0.304785126485827

! m2/m => ft2/ft 3.281

! L/day => pint/day 2.11337629827348

! L/kWh => pint/kWh 2.11337629827348

! kg/Pa-s-m2 => lb/psi-s-ft2 1412.00523459398

! m/hr => ft/hr 3.281

! Mode => Mode 1

! Control => Control 1

! Availability => Availability 1

! rev/min => rev/min 1

! W/(m3/s) => W/(ft3/min) 0.0004719475

! VA => VA 1

! N-m => lbf-in 8.85074900525547

! m3/s-W => ft3-h/min-Btu 621.099127332943

! cm2 => inch2 0.15500031000062

! kg/m => lb/ft 0.67196893069637

! m/yr => inch/yr 39.37

!

! Other conversions supported (needs the \ip-units code)

!

! m => in 39.37

! W => W 1

! m3/s => gal/min 15852

! m3/s => lbH2O/hr 7936289.998

! Pa => inHg 0.00029613

! Pa => inH2O 0.00401463

! Pa => ftH2O 0.00033455

! W/person => W/person 1

! W/m2 => W/m2 1

! W/m2 => W/ft2 0.0928939733269818

! W/m-K => Btu/h-ft-F 0.577796066000163

!

! Units fields that are not translated

! deg

! hr

! A

! dimensionless

! V

! ohms

! A/V

! eV

! percent

! s

! W/m2 or deg C

! W/m2, W or deg C

! minutes

! 1/hr

! **************************************************************************

In the descriptions below, the fields for each input object will be described. Refer to the Energy+.idd for complete specifications. Energy+.idd is a text file that can be viewed with many text editors or word processors. The Site:Location object will serve as an example.

Site:Location,

\unique-object

\min-fields 5

A1 , \field Name

\required-field

\type alpha

N1 , \field Latitude

\units deg

\minimum -90.0

\maximum +90.0

\default 0.0

\note + is North, - is South, degree minutes represented in decimal (i.e. 30 minutes is .5)

\type real

N2 , \field Longitude

\units deg

\minimum -180.0

\maximum +180.0

\default 0.0

\note - is West, + is East, degree minutes represented in decimal (i.e. 30 minutes is .5)

\type real

N3 , \field Time Zone

\note basic these limits on the WorldTimeZone Map (2003)

\units hr

\minimum -12.0

\maximum +14.0

\default 0.0

\note Time relative to GMT. Decimal hours.

\type real

N4 ; \field Elevation

\units m

\minimum -300.0

\maximum< 8900.0

\default 0.0

\type real

The IDD excerpt above is the complete definition as seen in the IDD file.

First, the object name is given. (Site:Location) This is followed by a comma in both the definition (IDD) and in an input file (IDF). In fact, all fields except the terminating field of an IDD class object and IDF object are followed by commas. The final field in an IDD class object or in an IDF object is terminated by a semi-colon.

Next is an alpha field, the location name. As noted above, for input, spaces are significant in this field. The main inputs for Site:Location are numeric fields. These are numbered (as is the alpha field) for convenience. The \ designations will show various information about the objects as described above in the IDD conventions discussion. Of importance for reading this document are the units and possible minimum and maximum values for a field.

There is automatic processing of the \minimum, \maximum and \default data for numeric fields. Any infractions of the \minimum, \maximum fields are automatically detected and messages will appear in the standard error file. After all the input is checked, infractions will cause program termination (before the bulk of the simulation is completed). Defaults are also enforced if you leave the numeric field blank.

Some objects need all the parameters listed by the definition; some do not. In the descriptions that follow, we will try to indicate which parts are optional. Usually, these will be the last fields in the object input or definition. Even if items are not used for a particular object (e.g. Multiplier in the FenestrationSurface:Detailed and type=Door), the field must be included unless it is the last field in the object. So, for this instance, one must include a multiplier field (must be numeric and would need to obey any \minimum, \maximum rules) for doors.

Two spreadsheet files are included with the installation:

n ExampleFiles.xls – shows many details about the included example files including highlights of features.

n ExampleFiles-ObjectsLink.xls – shows, for each object, the first three occurrences of that object in an example file.

In the descriptions below, we will endeavor to have each object’s output displayed as well as each of the outputs described. The output variables for a run are selected by choosing the Output:VariableDictionary object. This object displays the available output variables for a run on the eplusout.rdd (regular variables) and eplusout.mdd (meter variables) files. Two significant styles are available for these displays and the descriptions below may have one for some objects and another for other objects. The variables are the same but will look a bit different. For clarity, the two displays are shown below:

Note that the IDF-Editor can interpret both sets of files and assist you in getting output variables into your input files. But you will have to successfully run your input file first.

The Simple (or regular) display looks like the following figure and is interpreted:

Zone/HVAC – when the output is produced at the “Zone” timestep (ref: number of timesteps in each hour) or at the “HVAC” aka System timestep (which can vary for each hour).

Average/Sum – whether this is a averaged value over the reporting period (such as a temperature or rate) or whether this is a summed value over the reporting period. Reporting periods are specified in the Output:Variable or Output:Meter objects.

<Variable Name> -- The variable name one uses for reporting is displayed (e.g., Outdoor Dry Bulb) along with the units (e.g., [C]).

Example from the eplusout.rdd file:

Zone,Average,Outdoor Dry Bulb [C]

Zone,Average,Outdoor Dew Point [C]

Zone,Average,Outdoor Wet Bulb [C]

Zone,Average,Outdoor Humidity Ratio [kgWater/kgAir]

Zone,Average,Outdoor Relative Humidity [%]

Zone,Average,Outdoor Barometric Pressure [Pa]

Zone,Average,Wind Speed [m/s]

Zone,Average,Wind Direction [deg]

Zone,Average,Sky Temperature [C]

HVAC,Sum,Zone/Sys Sensible Heating Energy [J]

HVAC,Sum,Zone/Sys Sensible Cooling Energy [J]

HVAC,Average,Zone/Sys Sensible Heating Rate [W]

HVAC,Average,Zone/Sys Sensible Cooling Rate [W]

HVAC,Average,Zone/Sys Air Temperature [C]

HVAC,Average,Zone/Sys Air Temperature at Thermostat [C]

Note that the eplusout.mdd file is similar, but meters are only available at the Zone timestep.

Zone,Meter,Electricity:Facility [J]

Zone,Meter,ExteriorLights:Electricity [J]

Zone,Meter,Grounds Lights:ExteriorLights:Electricity [J]

Zone,Meter,EnergyTransfer:Facility [J]

Zone,Meter,EnergyTransfer:Building [J]

Zone,Meter,EnergyTransfer:Zone:R13WALL WALLS [J]

The IDF display has all the same information in an IDF-ready form (i.e., you could copy and paste it into your input file using a text editor).

Example from the eplusout.rdd file:

Output:Variable,*,Outdoor Dry Bulb,hourly; !- Zone Average [C]

Output:Variable,*,Outdoor Dew Point,hourly; !- Zone Average [C]

Output:Variable,*,Outdoor Wet Bulb,hourly; !- Zone Average [C]

Output:Variable,*,Outdoor Humidity Ratio,hourly; !- Zone Average [kgWater/kgAir]

Output:Variable,*,Outdoor Relative Humidity,hourly; !- Zone Average [%]

Output:Variable,*,Outdoor Barometric Pressure,hourly; !- Zone Average [Pa]

Output:Variable,*,Zone/Sys Sensible Heating Energy,hourly; !- HVAC Sum [J]

Output:Variable,*,Zone/Sys Sensible Cooling Energy,hourly; !- HVAC Sum [J]

Output:Variable,*,Zone/Sys Sensible Heating Rate,hourly; !- HVAC Average [W]

Output:Variable,*,Zone/Sys Sensible Cooling Rate,hourly; !- HVAC Average [W]

Output:Variable,*,Zone/Sys Air Temperature,hourly; !- HVAC Average [C]

Output:Variable,*,Zone/Sys Air Temperature at Thermostat,hourly; !- HVAC Average [C]

All of the same information appears in a slightly different form and defaults to “hourly” reporting frequency (which, of course, can be changed when you put it into your input file). The “*” is preselected so that you would be reporting for all those items.

This group of objects influences the simulation in various ways.

The Version object allows you to enter the proper version that your IDF was created for. This is checked against the current version of EnergyPlus and a Severe error issued (non-terminating) if it does not match the current version string. Note that versions are often significant and there is no guarantee that the older file will run in the newer versions of the program. See IDF Version Updater (Auxiliary Programs Document) for methods of changing the older files to newer versions.

The Timestep object specifies the "basic" timestep for the simulation. The value entered here is usually known as the Zone Timestep. This is used in the Zone Heat Balance Model calculation as the driving timestep for heat transfer and load calculations. The value entered here is the number of timesteps to use within an hour. Longer length timesteps have lower values for Number of Timesteps per Hour. For example a value of 6 entered here directs the program to use a zone timestep of 10 minutes and a value of 60 means a 1 minute timestep. The user’s choice for Number of Timesteps per Hour must be evenly divisible into 60; the allowable choices are 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, and 60.

The choice made for this field has important implications for modeling accuracy and the overall time it takes to run a simulation. Here are some considerations when choosing a value:

· The solution technique used in EnergyPlus has been designed to be stable with zone timesteps of up to sixty minutes (Number Timesteps in Hour = 1). However, 60 minutes is considered a “long” timestep and it should only be used in rare occasions where there is no HVAC system, accuracy is not a concern, and short run times are critical. Such long timesteps are not recommended to use because simulation results are more accurate for shorter timesteps, of say 10 minutes or less (Number of Timesteps per Hour of 6 or more). Shorter zone timesteps improve the numerical solution of the Zone Heat Balance Model because they improve how models for surface temperature and zone air temperature are coupled together. Longer timesteps introduce more lag and lead to more a dampened dynamic response.

· Simulation run time increases with shorter timesteps or larger values for Number of Timesteps per Hour. The effect varies with the nature of the model. The user can test out different values on their particular model to understand the implications for his or her particular case. Sometimes large models with multizone HVAC and Plant systems execute nearly as fast with 15 minute timesteps as with 60 minute timesteps because fewer iterations are required in the system modeling since the prior timestep’s results are close to the final outcome of next timestep.

· The weather data files usually have 60-minute (or hourly) data. However, it does not follow that this should be used as the basis for choosing the zone timestep because:

o EnergyPlus carefully interpolates the weather data between data points for use at shorter timesteps. This is discussed in a later section: Weather Data Hourly Interpolation

o Many aspects of a model have time scales that differ from the that of the weather data. A goal of the modeling is to predict how the building will respond to the weather. However, the building’s response is not governed by the time scale that the weather data are available at, but rather the time scales of the dynamic performance of the thermal envelope as well as things like schedules for internal gains, thermostats, and equipment availability.

· If the model will include calculating the cost of electricity, then the user should be aware that many electric utility tariffs base charges on demand windows of a specified length of time. If the choice of Number of Timesteps per Hour is not consistent with the demand window, then unexpected results may be obtained. For reasonable prediction of the maximum rates for electricity use for in calculating demand charges, the length of the zone timestep needs to be consistent with the tariff’s demand window. The following table lists what values are consistent with various demand windows.

|

Demand Window |

Applicable Number of Timesteps per Hour |

|

QuarterHour |

4, 12, 20, or 60 |

|

HalfHour |

2, 4, 6, 10, 12, 20, 30, or 60 |

|

FullHour, Day, Week |

Any |

There is also second type of timestep inside EnergyPlus that is known as the System Timestep. This is a variable-length timestep that governs the driving timestep for HVAC and Plant system modeling. The user cannot directly control the system timestep (except by use of the ConvergenceLimits object). When the HVAC portion of the simulation begins its solution for the current zone timestep, it uses the zone timestep as its maximum length but then can reduce the timestep, as necessary, to improve the solution. The technical details of the approach are explained in the Engineering Documentation under "Integrated Solution Manager".

Users can see the system timestep used if they select the "detailed" frequency option on an HVAC report variable (e.g. Zone/Sys Air Temperature). To contrast, the "Zone" variables will only be reported on the zone timestep (e.g. Zone Mean Air Temperature).

And, the IDF example:

Timestep, 6; !Suggested default for most system simulations

Suggested defaults are 4 for non-HVAC simulations, 6 for simulations with HVAC, 20 is the minimum for ConductionFiniteDifference and HeatAndMoistureFiniteElement simulations. Green roof (ref: Material:RoofVegetation) also may require more timesteps.

Note that hourly data (such as outdoor conditions expressed by Design Days or Weather data) are interpolated to the Zone Timestep. This is discussed in a later section: Weather Data Hourly Interpolation

This item is an “advanced” feature that should be used only with caution. It is specifically included to assist some users “speed up” calculations while not overly compromising accuracy. The user must judge for him/herself whether the reduced run time is useful.

Usually the minimum system timestep is allowed to vary from the zone timestep (as maximum) to a minimum timestep of 1 minute during certain system calculations. This might be when the system turns on or off, for example. Entering 0 in this field sets the minimum system timestep to be the same as the zone timestep. Otherwise the units of the field are minutes. It’s probably a good idea to have any minimum entered be a divisor of the zone timestep.

The HVAC Manager will iterate to a solution or up to a set number of iterations. If not “converged”, then a warning error appears:

SimHVAC: Maximum iterations (20) exceeded for all HVAC loops, at CHICAGO IL USA TMY2-94846 WMO#=725300, 10/07 14:06 - 14:08

In order to reduce time used in simulating your building, you may choose to enter a lesser number than the default of 20 for the maximum number of iterations to be used. Or, you may wish to enter a bigger number for certain buildings. To get more information printed with a “max iteration” message, you need to enter a “Output:Diagnostics, DisplayExtraWarnings;” command (which may also generate other warnings than just this one).

Use in an IDF:

ConvergenceLimits,

0; ! Minimum System Timestep (0=same as zone timestep)

The Building object describes parameters that are used during the simulation of the building. There are necessary correlations between the entries for this object and some entries in the Site:WeatherStation and Site:HeightVariation objects, specifically the Terrain field.

Building name is specified for output convenience.

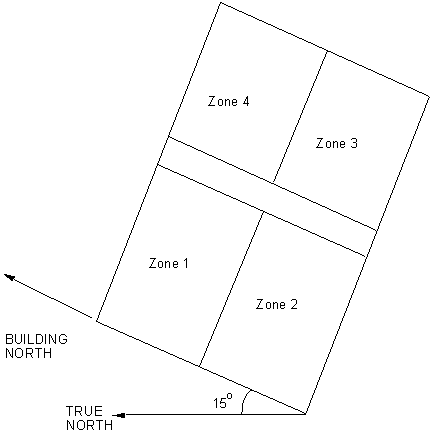

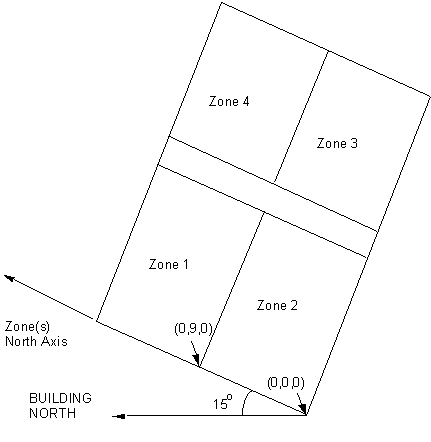

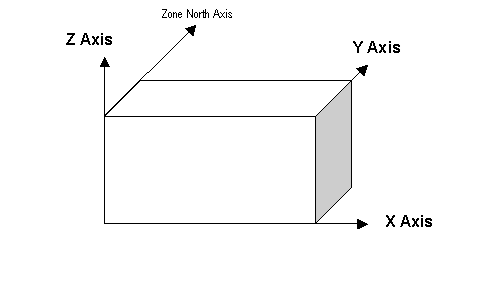

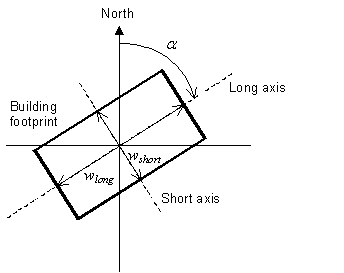

The Building North Axis is specifiedrelative to true North. Buildings frequently do not line up with true north. For convenience, one may enter surfaces in a “regular” coordinate system and then shift them via the use of the North Axis. The value is specified in degrees from “true north” (clockwise is positive).

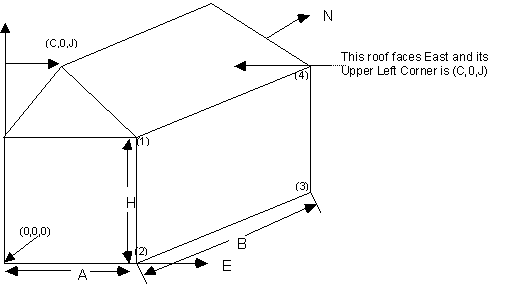

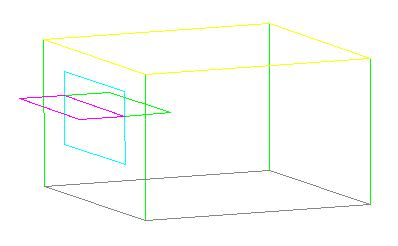

The figure below shows how the building north axis can be rotated to correspond with one of the major axes of an actual building. The relevance of this field is described more completely under “GlobalGeometryRules”; in particular, the value of “North Axis” is ignored if a coordinate system other than “relative” is used.

Figure 1. Illustration of Building North Axis

The site’s terrain affects how the wind hits the building – as does the building height. In addition, the external conduction method usually has its own parameters for the calculation. Please see the Engineering Documentation, External Conduction section for particulars. The legal values for this field are shown in the following table.

Table 1. Values for "Terrain"

|

Terrain Type Value |

Terrain Description |

|

Country |

Flat, Open Country |

|

Suburbs |

Rough, Wooded Country, Suburbs |

|

City |

Towns, city outskirts, center of large cities |

|

Ocean |

Ocean, Bayou flat country |

|

Urban |

Urban, Industrial, Forest |

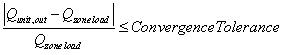

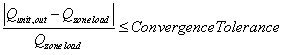

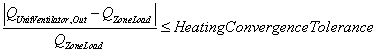

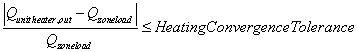

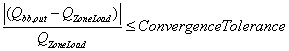

The following two fields along with the minimum and maximum number of warmup days (also in this object) define the user specified criteria for when EnergyPlus will “converge” at each environment (each sizing period or run period set as Yes in the SimulationControl object). EnergyPlus “runs” the first day of the environment (starting with a set of hard-coded initial conditions) until the loads/temperature convergence tolerance values are satisfied (next two fields) or until it reaches “maximum number of warmup days”. Note that setting the convergence tolerance values too loose will cause the program to be satisifed too early and you may not get the results you expect from the actual simulation.

This value represents the number at which the loads values must agree before “convergence” is reached. Loads tolerance value is a fraction of the load.

This value represents the number at which the zone temperatures must agree (from previous iteration) before “convergence” is reached. (Units for this field is delta C).

Convergence of the simultaneous heat balance/HVAC solution is reached when either the loads or temperature criterion is satisfied.

All tolerances have units so the temperature tolerance is in degrees C (or degrees K) and the loads tolerance is in Watts. Both tolerances work the same way, just one looks at temperatures and one looks at heating and cooling loads. After the second warm-up day, the program compares the maximum temperature experienced in a space with the maximum temperature from the previous day. If those two temperatures are within the tolerance, then it has passed the first warm-up check.

It does a similar comparison with lowest temperatures experience within all the zones. If the current simulation day and the previous day values are within the tolerance, then it has passed the second warm-up check. Similar things are done with the loads tolerance and the maximum heating and cooling loads that are experienced within the spaces. Those are compared individually to the values for the previous day. If they are both in tolerance, then the simulation has passed the third and fourth warm-up check. The simulation stays in the warm-up period until ALL FOUR checks have been passed.

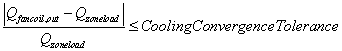

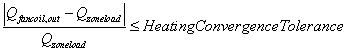

Please note--other "convergence tolerance" inputs are required for certain HVAC equipment (unit ventilator, unit heater, window AC, etc.). The purpose and units of these parameters are different from "load convergence tolerance" and "temperature convergence tolerance" in the BUILDING object.

Setting this value determines how EnergyPlus treats beam solar radiation and reflectances from exterior surfaces that strike the building and, ultimately, enter the zone. There are five choices: MinimalShadowing, FullExterior and FullInteriorAndExterior, FullExteriorWithReflections, FullInteriorAndExteriorWithReflections.

MinimalShadowing

In this case, there is no exterior shadowing except from window and door reveals. All beam solar radiation entering the zone is assumed to fall on the floor, where it is absorbed according to the floor's solar absorptance. Any reflected by the floor is added to the transmitted diffuse radiation, which is assumed to be uniformly distributed on all interior surfaces. If no floor is present in the zone, the incident beam solar radiation is absorbed on all interior surfaces according to their absorptances. The zone heat balance is then applied at each surface and on the zone's air with the absorbed radiation being treated as a flux on the surface.

FullExterior, FullExteriorWithReflections

In this case, shadow patterns on exterior surfaces caused by detached shading, wings, overhangs, and exterior surfaces of all zones are computed. As for MinimalShadowing, shadowing by window and door reveals is also calculated. Beam solar radiation entering the zone is treated as for MinimalShadowing -- All beam solar radiation entering the zone is assumed to fall on the floor, where it is absorbed according to the floor's solar absorptance. Any reflected by the floor is added to the transmitted diffuse radiation, which is assumed to be uniformly distributed on all interior surfaces. If no floor is present in the zone, the incident beam solar radiation is absorbed on all interior surfaces according to their absorptances. The zone heat balance is then applied at each surface and on the zone's air with the absorbed radiation being treated as a flux on the surface.

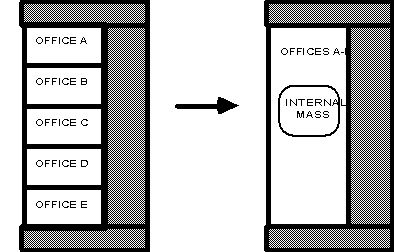

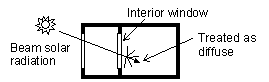

FullInteriorAndExterior, FullInteriorAndExteriorWithReflections

This is the same as FullExterior except that instead of assuming all transmitted beam solar falls on the floor the program calculates the amount of beam radiation falling on each surface in the zone, including floor, walls and windows, by projecting the sun's rays through the exterior windows, taking into account the effect of exterior shadowing surfaces and window shading devices.

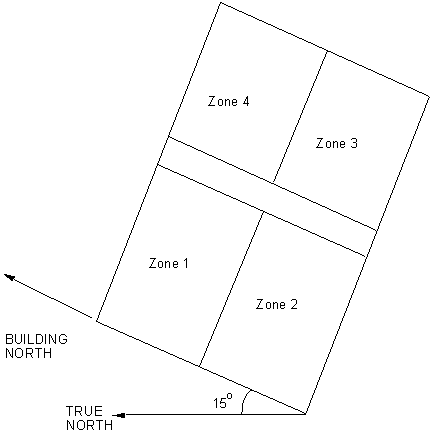

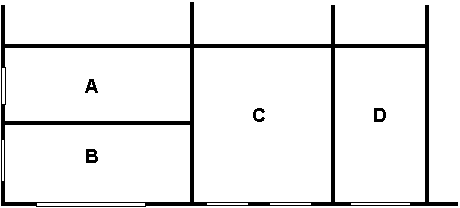

If this option is used, you should be sure that the surfaces of the zone totally enclose a space. This can be determined by viewing the eplusout.dxf file with a program like AutoDesk’s Volo View Express. You should also be sure that the zone is convex. Examples of convex and non-convex zones are shown in Figure 2. The most common non-convex zone is an L-shaped zone. (A formal definition of convex is that any straight line passing through the zone intercepts at most two surfaces.) If the zone’s surfaces do not enclose a space or if the zone is not convex you should use Solar Distribution = FullExterior instead of FullInteriorAndExterior.

If you use FullInteriorAndExterior the program will also calculate how much beam radiation falling on the inside of an exterior window (from other windows in the zone) is absorbed by the window, how much is reflected back into the zone, and how much is transmitted to the outside. In this calculation the effect of a shading device, if present, is accounted for.

Figure 2. Illustration of Convex and Non-convex Zones

Reflection calculations

Note: Using the reflection calculations can be very time-consuming. Even error-prone. As a possible alleviation, you can use the Output:Diagnostics,DoNotMirrorDetachedShading; in many cases to get past a fatal error.

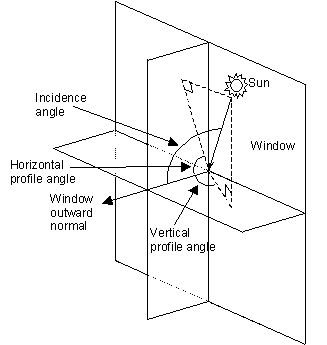

If using reflections, the program calculates beam and sky solar radiation that is reflected from exterior surfaces and then strikes the building. These reflecting surfaces fall into three categories:

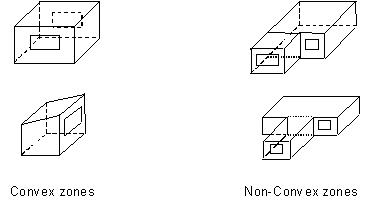

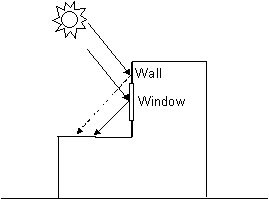

1) Shadowing surfaces. These are surfaces like overhangs or neighboring buildings entered with Surface Shading:Site:Detailed, Shading:Building:Detailed, or Shading:Zone:Detailed. See Figure 3.

2) These surfaces can have diffuse and/or specular (beam-to-beam) reflectance values that are specified with the Shading Surface Reflectance object (ref: ShadingProperty:Reflectance).

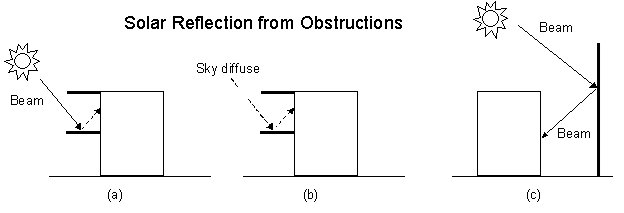

3) Exterior building surfaces. In this case one section of the building reflects solar radiation onto another section (and vice-versa). See Figure 4.

4) The building surfaces are assumed to be diffusely reflecting if they are opaque (walls, for example) and specularly reflecting if they are windows or glass doors. The reflectance values for opaque surfaces are calculated by the program from the Solar Absorptance and Visible Absorptance values of the outer material layer of the surface’s construction (ref: Material properties). The reflectance values for windows and glass doors are calculated by the program from the reflectance properties of the individual glass layers that make up surface’s construction assuming no shading device is present and taking into account inter-reflections among the layers (ref: Window Properties).

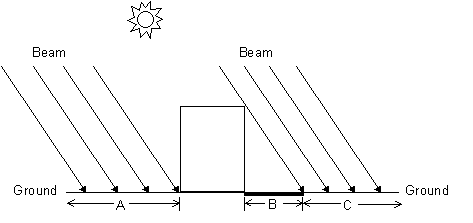

5) The ground surface. Reflection from the ground is calculated even if reflections option is not used. But in this case the ground plane is considered unobstructed, i.e., the shadowing of the ground by the building itself or by obstructions such as neighboring buildings is ignored. This shadowing is taken into account if the reflections option is used.[1] This is shown in Figure 5.

Figure 3. Solar reflection from shadowing surfaces. Solid arrows are beam solar radiation; dashed arrows are diffuse solar radiation. (a) Diffuse reflection of beam solar radiation from the top of an overhang. (b) Diffuse reflection of sky solar radiation from the top of an overhang. (c) Beam-to-beam (specular) reflection from the façade of an adjacent highly-glazed building represented by a vertical shadowing surface.

Figure 4. Solar reflection from building surfaces onto other building surfaces. In this example beam solar reflects from a vertical section of the building onto a roof section. The reflection from the window is specular. The reflection from the wall is diffuse.

Figure 5. Shadowing from building affects beam solar reflection from the ground. Beam-to-diffuse reflection from the ground onto the building occurs only for sunlit areas, A and C, not from shaded area, B.

This field specifies the number of “warmup” days that might be used in the simulation before “convergence” is achieved. The default number, 25, is usually more than sufficient for this task; however, some complex buildings (with complex constructions) may require more days. An error message will occur when the simulation “runs” out of days, fort each zone:

CheckWarmupConvergence: Loads Initialization, Zone="MAIN ZONE" did not converge after 30 warmup days.

See Warmup Convergence Information in .eio file for details

..Environment(SizingPeriod)="DENVER CENTENNIAL GOLDEN N ANN CLG 1% CONDNS DB=>MWB"

..Max Temp Comparison = 2.06E-002 vs Temperature Convergence Tolerance=0.50 – Pass Convergence

..Min Temp Comparison = 5.95E-003 vs Temperature Convergence Tolerance=0.50 – Pass Convergence

..Max Cool Load Comparison = 9.5082E-002 vs Loads Convergence Tolerance=5.00E-002 – Fail Convergence

As noted in the message, there will be more information in the .eio file. (Refer to Output Details document as well for examples.)

You may be able to increase the Maximum Number of Warmup Days and get convergence, but some anomalous buildings may still not converge. Simulation proceeds for x warmup days until “convergence” is reached (see the discussion under the Temperature Convergence Tolerance Value field in this object, just above).

The minimum number of warmup days that produce enough temperature and flux history to start EnergyPlus simulation for all reference buildings was suggested to be 6. When this field is greater than the maximum warmup days defined previous field the maximum number of warmup days will be reset to the minimum value entered here. Warmup days will be set to be the value you entered when it is less than the default 6. The selection of 6 as a minimum was done after careful study using the 400+ test suite files that we use in development.

An example from an IDF:

Building,

PSI HOUSE DORM AND OFFICES, !- Name

36.87000, !- North Axis {deg}

Suburbs, !- Terrain

0.04, !- Loads Convergence Tolerance Value

0.4000000, !- Temperature Convergence Tolerance Value {deltaC}

FullInteriorAndExterior, !- Solar Distribution

40, !- Maximum Number of Warmup Days

6; !- Minimum Number of Warmup Days

This input object is used control the choice of models used for surface convection at the inside face of all the heat transfer surfaces in the model. This object sets the selection for convection correlations in a global way. The Zone Inside Convection Algorithm input field in the Zone object may be used to selectively override this value on a zone-by-zone basis. Further, individual surfaces can refine the choice by each surface or surface lists – see object SurfaceProperty:ConvectionCoefficients and object SurfaceProperty:ConvectionCoefficients:MultipleSurface.

The model specified in this field is the default algorithm for the inside face all the surfaces.. The key choices are Simple, TARP, CeilingDiffuser, and AdaptiveConvectionAlgorithm.

The Simple model applies constant heat transfer coefficients depending on the surface orientation.

The TARP model correlates the heat transfer coefficient to the temperature difference for various orientations. This model is based on flat plate experiments.

The CeilingDiffuser model is a mixed and forced convection model for ceiling diffuser configurations. The model correlates the heat transfer coefficient to the air change rate for ceilings, walls and floors. These correlations are based on experiments performed in an isothermal room with a cold ceiling jet. To avoid discontinuities in surface heat transfer rate calculations, all of correlations have been extrapolated beyond the lower limit of the data set (3 ACH) to a natural convection limit that is applied during the hours when the system is off.

The AdaptiveConvectionAlgorithm model is an dynamic algorithm that organizes a large number of different convection models and automatically selects the one that best applies. The adaptive convection algorithm can also be customized using the SurfaceConvectionAlgorithm:Inside:AdaptiveModelSelections input object. These models are explained in detail in the EnergyPlus Engineering Reference Document. The default is AdaptiveConvectionAlgorithm.

IDF Example:

SurfaceConvectionAlgorithm:Inside,TARP;

Various exterior convection models may be selected for global use. The optional Zone Outside Convection Algorithm input field in the Zone object may be used to selectively override this value on a zone-by-zone basis. Further, individual surfaces can refine the choice by each surface or surface lists – see object SurfaceProperty:ConvectionCoefficients and object SurfaceProperty:ConvectionCoefficients:MultipleSurface.

The available key choices are SimpleCombined, TARP, MoWiTT, DOE-2, and AdaptiveConvectionAlgorithm.

The Simple convection model applies heat transfer coefficients depending on the roughness and windspeed. This is a combined heat transfer coefficient that includes radiation to sky, ground, and air. The correlation is based on Figure 1, Page 25.1 (Thermal and Water Vapor Transmission Data), 2001 ASHRAE Handbook of Fundamentals. Note that if Simple is chosen here or in the Zone field and a SurfaceProperty:ConvectionCoefficients object attempts to override the caulcation with a different choice, the action will still be one of combined calculation. To change this, you must select one of the other methods for the global default.

All other convection models apply heat transfer coefficients depending on the roughness, windspeed, and terrain of the building’s location. These are convection only heat transfer coefficients; radiation heat transfer coefficients are calculated automatically by the program.

The TARP algorithm was developed for the TARP software and combines natural and wind-driven convection correlations from laboratory measurements on flat plates.

The DOE-2 and MoWiTT were derived from field measurements. DOE-2 uses a correlation from measurements by Klems and Yazdanian for rough surfaces. MoWitt uses a correlation from measurements by Klems and Yazdanian for smooth surfaces and, therefore, is most appropriate for windows (see SurfaceProperty:ConvectionCoefficients:MultipleSurface for how to apply to only windows).

The AdaptiveConvectionAlgorithm model is an dynamic algorithm that organizes a large number of different convection models and automatically selects the one that best applies. The adaptive convection algorithm can also be customized using the SurfaceConvectionAlgorithm:Outside:AdaptiveModelSelections input object. All algorithms are described more fully in the Engineering Reference.

Note that when the surface is wet (i.e. it is raining and the surface is exposed to wind) then the convection coefficient appears as a very large number (1000) and the surface is exposed to the Outdoor Wet-bulb Temperature rather than the Outdoor Dry-bulb Temperature.

IDF Example:

SurfaceConvectionAlgorithm:Outside, AdaptiveConvectionAlgorithm;

The HeatBalanceAlgorithm object provides a way to select what type of heat and moisture transfer algorithm will be used across the building construction calculations.

Four values are allowed to select which solution will be used.

n The ConductionTransferFunction selection is a sensible heat only solution and does not take into account moisture storage or diffusion in the construction elements.

n The MoisturePenetrationDepthConductionTransferFunction selection is a sensible heat diffusion and an inside surface moisture storage algorithm that also needs additional moisture material property information. Sometimes, this is referred to as the Effective Moisture Penetration Depth or EMPD. See the moisture material property object for additional information and description of outputs:

n MaterialProperty:MoisturePenetrationDepth:Settings

n Advanced/Research usage: The ConductionFiniteDifference selection is a sensible heat only solution and does not take into account moisture storage or diffusion in the construction elements. This solution technique uses a 1-D finite difference solution in the construction elements. Outputs for the surfaces are described with the material property objects. The Conduction Finite Difference (aka CondFD) property objects are:

n MaterialProperty:PhaseChange

n MaterialProperty:VariableThermalConductivity

n Advanced/Research usage: The ConductionFiniteDifferenceSimplified selection is a sensible heat only solution and does not take into account moisture storage or diffusion in the construction elements. This solution technique uses a 1-D finite difference solution in the construction elements – representing only two nodes per construction. Outputs for the surfaces are described with the material property objects. The Conduction Finite Difference Simplified property objects are:

n MaterialProperty:VariableThermalConductivity

n Construction:UseHBAlgorithmCondFDDetailed

n Advanced/Research usage: The CombinedHeatAndMoistureFiniteElement is a coupled heat and moisture transfer and storage solution. The solution technique uses a one dimensional finite difference solution in the construction elements and requires further material properties described in the Heat and Moisture Transfer material properties objects. Outputs from the algorithm are described with these objects. The Heat and Moisture Transfer property objects are:

n MaterialProperty:HeatAndMoistureTransfer:Settings

n MaterialProperty:HeatAndMoistureTransfer:SorptionIsotherm

n MaterialProperty:HeatAndMoistureTransfer:Suction

n MaterialProperty:HeatAndMoistureTransfer:Redistribution

n MaterialProperty:HeatAndMoistureTransfer:Diffusion

n MaterialProperty:HeatAndMoistureTransfer:ThermalConductivity

This field is a bit “advanced”. It should only be used when the simulation fails AND you cannot determine a cause for the failure. That is, you receive an error similar to:

** Severe ** Temperature out of bounds (202.91) for surface=Wall1

** ~~~ ** in Zone=Zone01

** ~~~ ** Occurrence info=NEW YORK CITY NY SUMMER, 07/21 16:00 - 16:01

** ~~~ ** A temperature out of bounds problem can be caused by several things. The user

** ~~~ ** should check the weather environment, the level of internal gains with respect

** ~~~ ** to the zone, and the thermal properties of their materials among other things.

** ~~~ ** A common cause is a building with no thermal mass -- all materials with

** ~~~ ** Regular-R definitions.